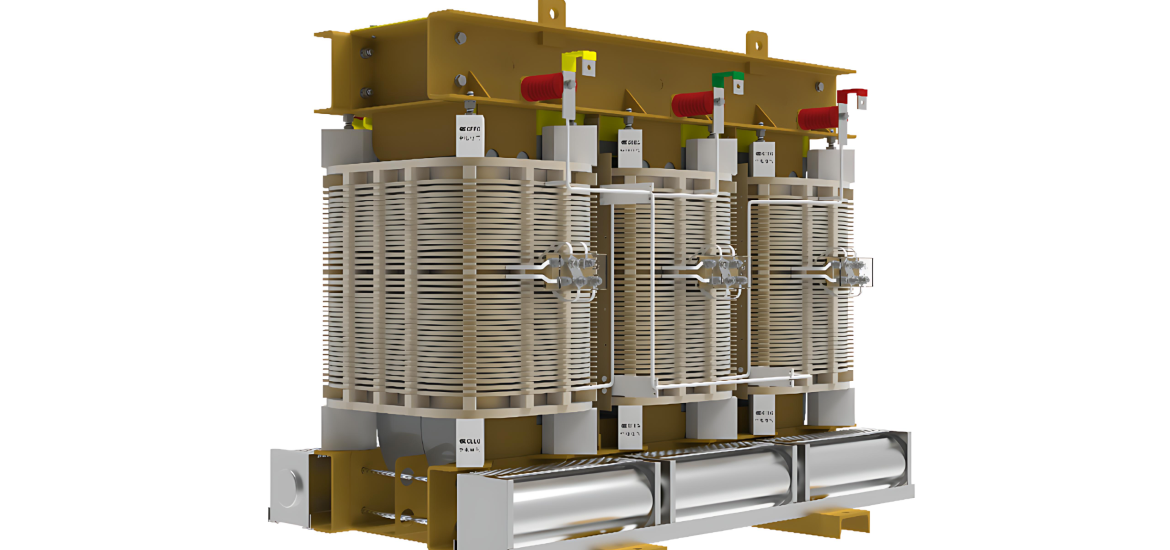

For decades, specifying surge protection involved a fundamental trade-off. Engineers had to choose between lower protective levels or higher temporary overvoltage (TOV) withstand capability. Achieving one often meant sacrificing the other. This compromise left critical assets, like power transformers, caught in the middle.

New technology now offers a mature and highly refined product to eliminate this dilemma. The Gapped MOV (Metal Oxide Varistor) Surge Arrester provides both superior protective levels and substantially higher TOV capability simultaneously.

By re-engineering the relationship between the switching and energy-absorbing components, the Gapped MOV arrester represents a premier protective technology, not as a mere alternative, but as the superior choice for critical applications.

The Core Principle: A Strategic Separation of Duties

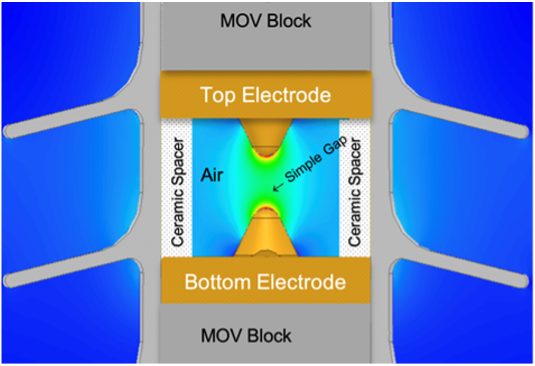

The superior performance of the gapped MOV arrester comes from one design principle: separating the roles of the internal components. Unlike conventional gapless arresters, where the MOV disks must handle continuous system voltage, the Gapped MOV design assigns specific tasks to the components best suited for them.

- The Series Gap: The Turn-On Switch

Acting as a high-speed, voltage-controlled switch, the series gap isolates the MOV disks from the line under normal conditions. When a transient over-voltage occurs, the gas in the gap sparks over in an instant, “closing” the switch and engaging the MOV disks.

- The MOV Disks: The Turn-Off Switch

Once the gap activates, the MOV disks perform their primary function: shunting the damaging surge current safely to ground. As soon as the surge passes and voltage returns to normal, the MOV disks’ highly non-linear properties cause them to immediately stop conducting significant current. They effectively “turn off” the event with an extremely rapid response long before the system voltage reaches a zero crossing.

In a gapped MOV arrester, the roles are separated: the gap is the turn-on switch, and the MOV disks are the turn-off switch.

This intelligent separation of duties is the key that unlocks a new level of performance, eliminating the design trade-offs inherent in gapless arresters.

Eliminating the Agent of Degradation: Power Follow-Current

The most significant consequence of the Gapped MOV’s operating principle is the complete elimination of power follow-current.

In older gapped Silicon Carbide (SiC) technology, after the initial surge, hundreds of amps from the power system would “follow” the path to ground until the AC wave passed through a zero crossing. This sustained, damaging current was the primary cause of gap degradation and erosion over time, leading to unstable performance.

Because the Gapped MOV arrester’s MOV disks extinguish the current almost instantly, the follow-current never has a chance to form. The gaps are only subjected to the brief surge, not the destructive 50/60 Hz power current. This absence of follow-current means the gaps do not degrade, ensuring stable and reliable performance throughout the arrester’s life.

The Evolution to Zero-Loss Performance

Modern designs have evolved even further. The move from older resistively graded gaps to capacitively graded gaps has created arresters with nearly zero watts loss during steady-state operation. This innovation also yields a flat TOV curve, allowing the arrester to withstand overvoltages indefinitely without a time limit.

The Result: Quantifiable and Decisive Advantages

The unique design of the Gapped MOV arrester translates directly into distinct, quantifiable performance benefits that enhance grid reliability and protect critical assets.

- Superior Protective Levels

Because the MOV disks are isolated, they can be optimized for a lower reference voltage. This results in clamping voltages as much as 25-30% better than conventional designs, providing a greater margin of protection for equipment insulation.

- Enhanced TOV Capability

The series gap makes the arrester “untouchable” by most voltage swells from system faults, preventing the MOV disks from going into thermal runaway. Modern designs can withstand 1.78 per unit MCOV indefinitely.

- Improved Energy Handling

The MOV disks are not subjected to post-surge power consumption while hot, meaning the arrester dissipates less total energy internally and experiences a lower temperature rise.

- Environmental Benefits

With nearly zero watts loss, capacitively graded gapped MOV arresters are highly efficient. On a system-wide scale, this efficiency translates into a substantial annual reduction of COâ‚‚ emissions compared to standard ungapped arresters.

Standardized and Proven: High Performance Celeco® Surge Protection Technology

Gapped MOV arrester designs are fully recognized by international standards, including IEEE C62.11 and IEC 60099-6. These standards ensure users can confidently apply this technology, knowing it has passed rigorous tests designed to simulate real-world conditions.

Weidmann partners with leading manufacturers to provide a comprehensive portfolio of transformer accessories, designed to detect, isolate, and mitigate electrical faults before they lead to equipment failure or costly downtime. This carefully selected range includes:

- Surge Advance Arrester

- Heavy Duty Distribution Arrester

- Riser Pole Arrester

Contact Weidmann by scanning the QR code to find out how Gapped MOV technology can optimize your system protection without compromise.

For more information: weidmann-electrical.com electrical@weidmann-group.com

This article was originally published in the October 2025 issue of the Advanced Insulation Soulutions: Condition Monitoring for a Safer Grid magazine.

View Magazine