Introduction

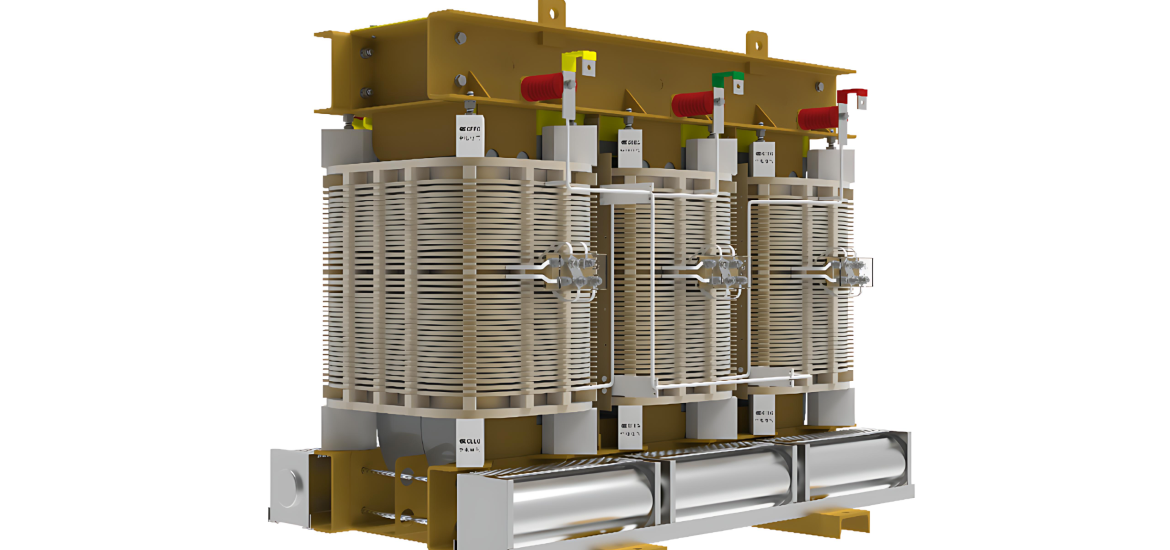

The reliability and longevity of power transformers depend heavily on their insulation system, which is particularly sensitive to temperature. Winding hot-spot temperature is the most critical parameter influencing insulation aging and, ultimately, transformer life expectancy. Traditionally, this value has been estimated using mathematical models and indirect measurement techniques, but these methods often lack accuracy and consistency. Recent advances in fiber optic sensing technologies now allow direct measurement of winding hot-spot temperatures. This article discusses why accurate temperature monitoring is crucial, the limitations of conventional methods, the benefits of fiber optic probes, and how utilities can leverage this technology for operational and economic advantages.

Why Monitor Winding Temperature?

Winding temperature is directly linked to the rate of insulation degradation. Studies show that around 60% of transformer failures are due to insulation problems, and inaccurate hot-spot temperature estimation is a leading cause of premature aging.

Accurate monitoring provides:

• Reliable insulation life assessment – Understanding the real hot-spot temperature enables precise calculation of aging acceleration factors.

• Cooling control – Real temperature data allows for more effective cooling system operation with reduced lag.

• Maximized loading and revenue generation – Operators can safely push units closer to their true MVA capacity, knowing the thermal limits.

• Standards compliance – IEC 60076-2 strongly recommends fiber optic probes in large transformers.

By accurately capturing winding hot-spot behavior, utilities can enhance asset management strategies, optimize maintenance intervals, and increase profitability without compromising transformer life.

Limitations of Conventional Methods

Heat-Run Tests and Average Temperatures:

Traditional temperature rise (“heat run”) tests only provide average winding temperatures under rated load. These results do not reflect the localized hot-spots where insulation is under greatest stress.

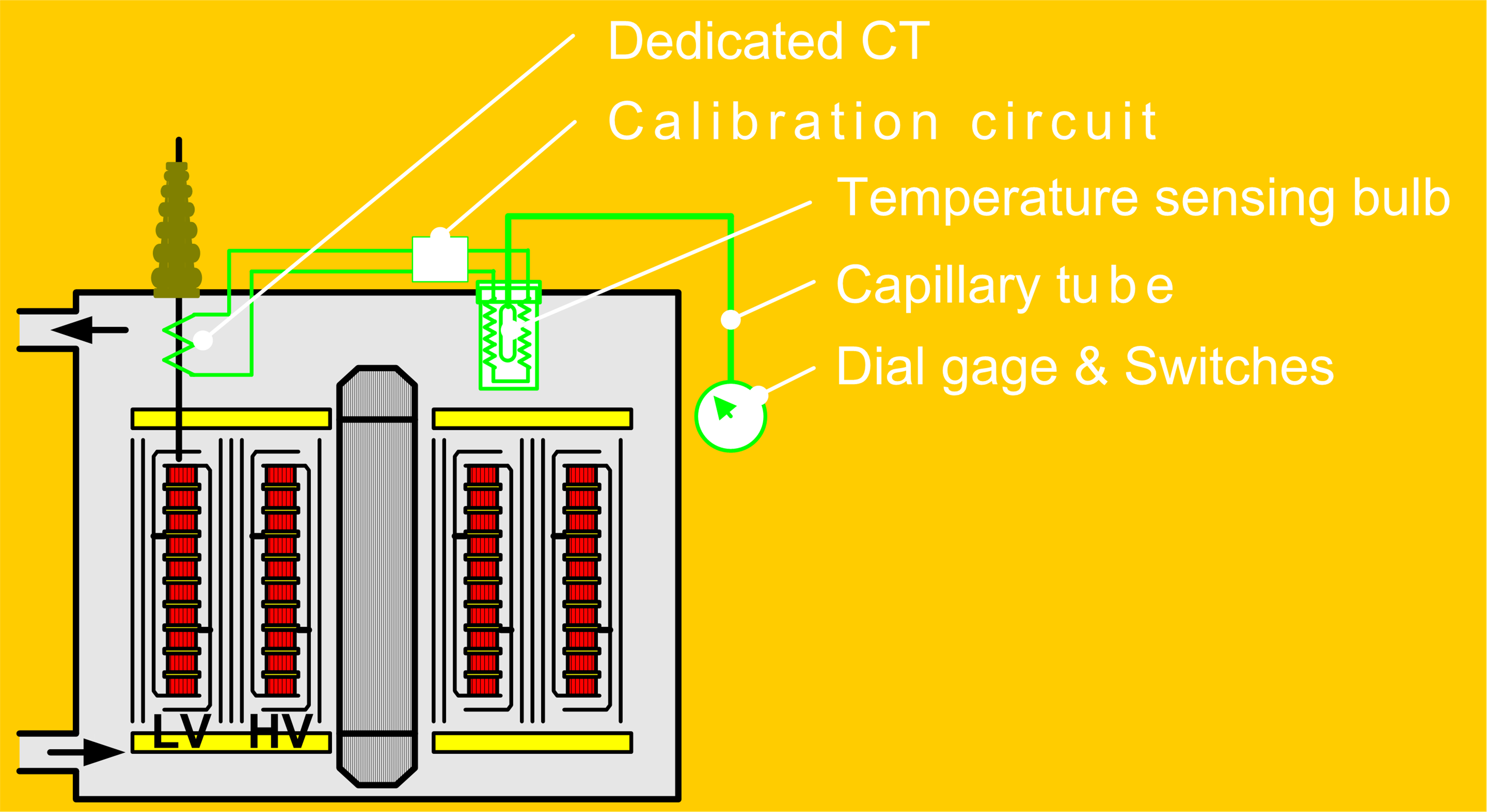

Winding Temperature Indicators (WTIs):

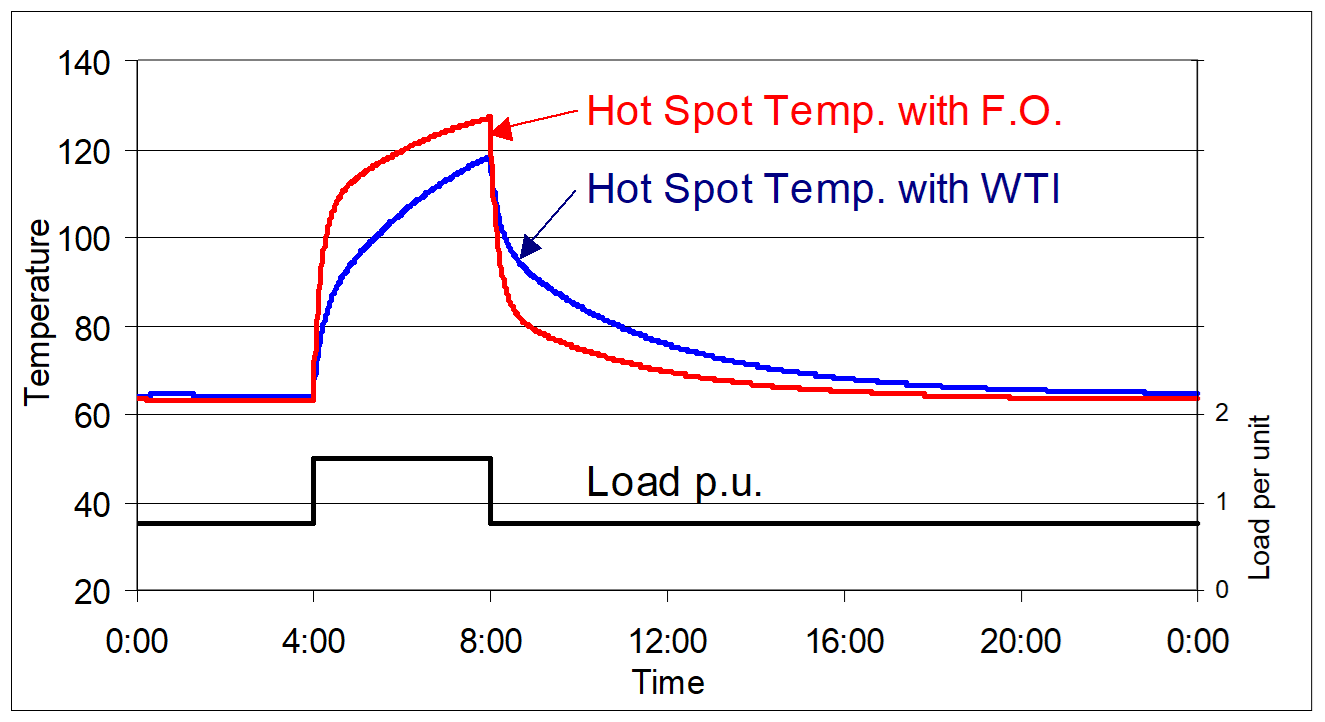

Modern WTIs, though more advanced than older analog devices, still simulate temperatures using indirect measurements and assumptions. They are often mis-calibrated and subject to errors of 5–10 °C or more. Their reliance on models means they cannot provide true hot-spot values. This inaccuracy has significant consequences: every 6–7 °C increase in hot-spot temperature approximately doubles the insulation aging acceleration factor. In practice, this means that if the measured temperature is underestimated by such a margin, the actual insulation life expectancy may be reduced by half.

Studies show that around 60% of transformer failures are due to insulation problems, and inaccurate hot-spot temperature estimation is a leading cause of premature aging.

Limitations of Conventional Methods

Mathematical Models:

For decades, loading guides such as IEEE C57.91 (1995) and IEC 60354 (1991) relied on simplified hot-spot estimation formulas. These models did not consider factors such as real oil temperature in ducts, resistance change with temperature, oil viscosity variation, tap changer effects, or oil inertia during sudden overloads. Although recent revisions introduce more sophisticated methods, they still depend on assumptions and data provided by manufacturers’ information that is not always available or validated. In summary; Conventional methods are approximations. For critical insulation health assessment and operational decision-making, they are insufficient.

Fiber Optic Technology: Direct Measurement

Direct measurement using fiber optic sensors eliminates the uncertainties of models and indirect devices.

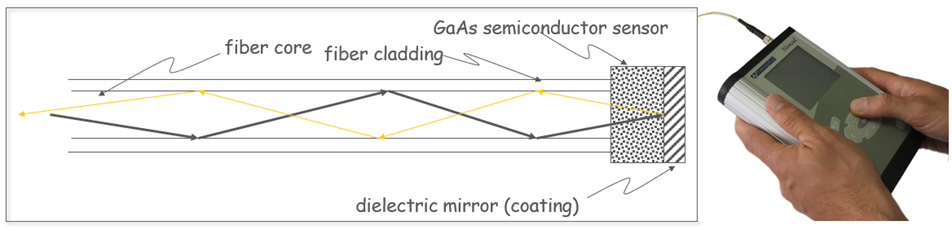

Operating Principle:

Fiber optic probes use a Gallium Arsenide (GaAs) semiconductor sensor, which shifts its light absorption characteristics with temperature. Light is delivered to the probe tip via an optical fiber and reflected for analysis. The result is a direct, drift-free temperature measurement with no recalibration required over the sensor’s lifetime.

By accurately capturing winding hot-spot behavior, utilities can enhance asset management strategies, optimize maintenance intervals, and increase profitability without compromising transformer life.

Fiber Optic Technology: Direct Measurement

Advantages Over Conventional Sensors:

• Immunity to electromagnetic interference

• Robust and chemically resistant construction

• No electrical conductors in the transformer (intrinsically safe)

• Minimal thermal shunting

• Long-term stability with no drift or recalibration

Installation Considerations:

Probes are typically placed near the winding hot-spot region, usually 1 to 3 disks below the winding top. Proper installation — such as embedding probes in radial spacers or using retaining disks — ensures durability, accurate readings, and protection against mechanical stress.

Fiber optic sensors have matured into a dependable, accurate, and maintenance-free solution for monitoring real winding temperatures.

Economic and Operational Benefits

Accurate hot-spot temperature measurement brings both technical and financial benefits. By enabling precise knowledge of winding temperatures, operators can safely maximize transformer loading without compromising insulation life. This supports dynamic loading strategies, improves the accuracy of cooling control, and allows for better planning of maintenance and replacement activities. Financially, accurate monitoring helps utilities reduce unexpected outages, avoid costly failures, and optimize asset utilization, ultimately translating into improved revenue and return on investment. Beyond economics, direct monitoring prevents catastrophic failures by detecting thermal stresses early, allowing utilities to optimize maintenance schedules and defer unnecessary replacements.

Standards and Future Trends

The role of fiber optic technology is reinforced by international standards:

• IEC 60076-2 dedicates a section to fiber optic sensor installations, clearly stating that direct measurement is preferred when hot-spot temperatures cannot be emulated.

• IEEE C57.91 already includes discussions on fiber sensors, with broader adoption expected in future revisions.

• Communication protocols such as IEC 61850 enable seamless integration of fiber optic monitoring into modern digital substations and smart grids.

This evolution reflects the industry’s recognition that direct measurement is essential for accurate transformer diagnostics and smart asset management.

Conclusion

Transformer aging is primarily driven by winding hot-spot temperature. As loading practices become more aggressive and operational demands increase, the limitations of traditional measurement methods are no longer acceptable. Fiber optic sensors have matured into a dependable, accurate, and maintenance-free solution for monitoring real winding temperatures. They provide operators with the data needed to safely maximize transformer utilization, extend asset life, and support the transition to smart grid environments. Investing in accurate hot-spot temperature monitoring is not just a technical choice — it is a strategic decision that safeguards reliability and maximizes the value of critical transformer assets.

Emilio Morales is a Technical Application Specialist in Transformer applications at Qualitrol Company LLC. He has over 30 years of experience in power transformer design, including units up to 500 MVA and 500 kV, as well as furnace and rectifier transformers and reactors. He is an active member of IEEE, IEC, and CIGRE, and has contributed to multiple industry working groups. Emilio holds a bachelor’s degree in Electromechanical Engineering from Nuevo Leon State University in Mexico.

This article was originally published in the October 2025 issue of the Advanced Insulation Soulutions: Condition Monitoring for a Safer Grid magazine.

View Magazine