Cables are often treated as “fit and forget” assets. Once installed, they vanish underground, behind walls, or into conduits, quietly powering our lives. But as Ben Lanz points out, most cable failures don’t come from age or wear… they start on day one. The way cables are installed, protected, and monitored dictates whether they will last a few years or over a century. And the good news is that success doesn’t require magic. As Lanz puts it, the recipe is simple: install them properly, protect them against extreme duty cycles, and then let them run.

Why Installation Matters More Than Anything

When it comes to long-term cable reliability, installation is the single most im portant factor. The vast majority of anomalies in cable systems exist from the very beginning, and almost all of them are caused by human interaction. Bend radius violations, poorly made splices, improper terminations, or even rough handling during shipping can introduce hidden defects that grow into failures years later.

The statistics are sobering. Around 40 percent of new installations contain at least one substandard component. That means four in ten systems are already carrying the seeds of future outages before they ever go live. And once a cable fails, the risk multiplies. A system that experiences one failure in the first decade of life is up to ten times more likely to fail again.

The lesson is clear: the best opportunity to prevent outages decades down the road is at the very start of a cable’s life. Careful installation, rigorous com missioning tests, and adherence to specifications are not just best practices, they are investments in the system’s future stability.

How the Environment Shapes Failure

Many people misunderstand how cables fail. At low voltages, under 1,000 volts, the primary issue is mechanical damage and gradual leakage currents. For alu minum conductors, oxidation slowly transforms good connections into open circuits, leading first to brownouts and eventually full outages.

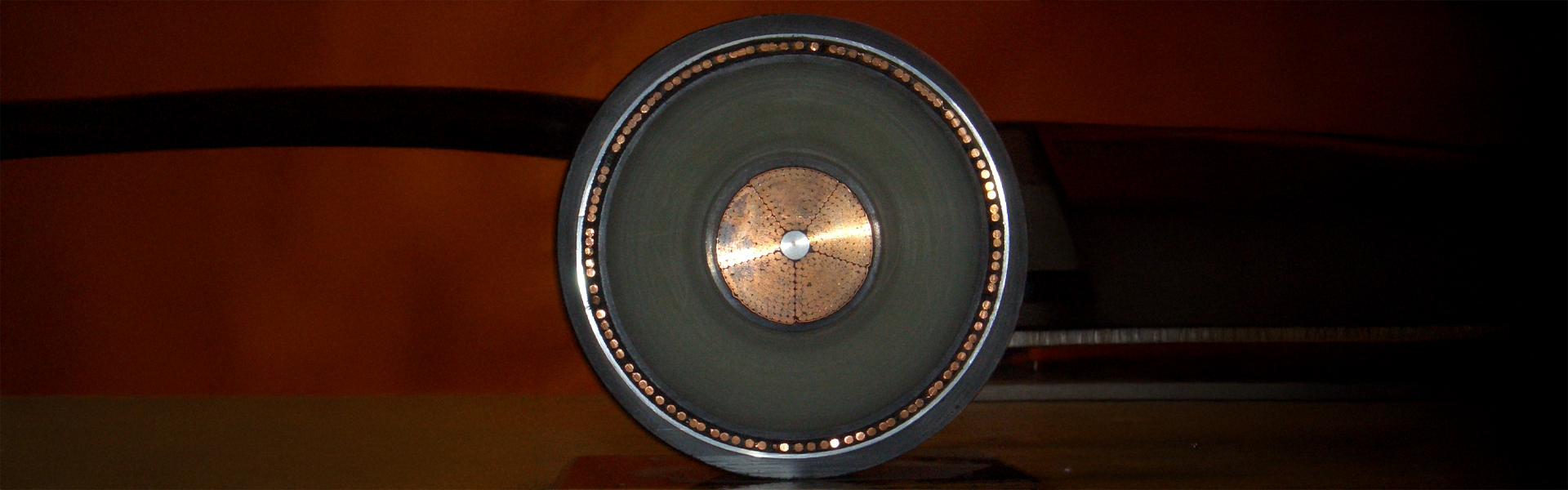

But once you move into medium- and high-voltage cable systems, above 5 kilovolts, the failure mechanisms shift dramatically. These cables, built in coaxial layers, are vulnerable to partial discharge, a microscopic erosion process caused by transient overvoltages. Power systems can experience microsecond bursts of extreme voltage. These tiny electrical storms turn hidden defects on and off, slowly eating through insulation over years or decades until full breakdown occurs.

This kind of intermittent erosion doesn’t happen continuously. It only grows under stress. That’s why protecting cables from extreme duty cycles, such as surges and overloads, is so important. Surge arresters, for example, aren’t just accessories; they’re lifelines that protect assets from voltage transients that accelerate failure.

The Myth of Water Trees

Anyone who has studied cable degradation has heard of water trees. They are often cited as silent killers that slowly weaken insulation. But Lanz challenges this conventional wisdom. Water doesn’t fail cables. Electrical trees do. Water trees only form when there is already an anomaly in the system, usually caused by a manufacturing defect or poor installation.

Water, being a polar molecule, is drawn to areas of high electric stress. If a defect creates stress in one part of the insulation, moisture concentrates there. Under the right conditions, such as a wet-dry interface combined with an existing defect, the stage is set for electrical treeing. This process can grow over time, but even then it only expands during transient events.

The takeaway? Water trees are not the universal threat they are often portrayed to be. They are symptoms of deeper quality control problems. If cables are built and installed correctly, random moisture is not enough to doom them.

Predictive Maintenance as a Lifeline

Even if defects slip through, predictive maintenance offers a second chance. Offline partial discharge testing at 50 or 60 hertz can identify hidden weaknesses with incredible sensitivity. This is the same benchmark manufacturers use for quality control. Conducted in the field, meter by meter and foot by foot, these scans reveal substandard splices, joints, and terminations that would otherwise go unnoticed.

Once identified, those defects can be repaired or replaced, restoring the system to its intended performance. Combined with protective measures like surge arresters and load management, this approach can double or triple the lifespan of cable systems. Instead of failing in 30 or 40 years, cables can last for 80, 90, or even 100 years.

A Simpler Way Forward

The recipe for reliability is not complicated. Start by making sure cables are installed correctly. Commission systems thoroughly to catch early defects. Once in service, protect against extreme operating conditions rather than performing constant intrusive inspections.

As Lanz argues, taking a cable out every couple of years “just to see if it’s still good” is a waste of time. Unless there’s been a surge event or an overload, a properly installed and protected system shouldn’t need attention for decades. In fact, if those first steps are done right, you shouldn’t need to touch a cable for at least 20 years.

That’s the real breakthrough: reliability doesn’t require over-engineering, exces sive maintenance, or endless testing. It comes from discipline at the start, sensi ble protection throughout, and the confidence to let well-built systems do what they were designed to do, quietly, invisibly, and reliably, for a lifetime.

Want the full picture?

Watch Ben Lanz’s RED Talk on cable reliability at RED Talks.

This article was originally published in the October 2025 issue of the Advanced Insulation Soulutions: Condition Monitoring for a Safer Grid magazine.

View Magazine