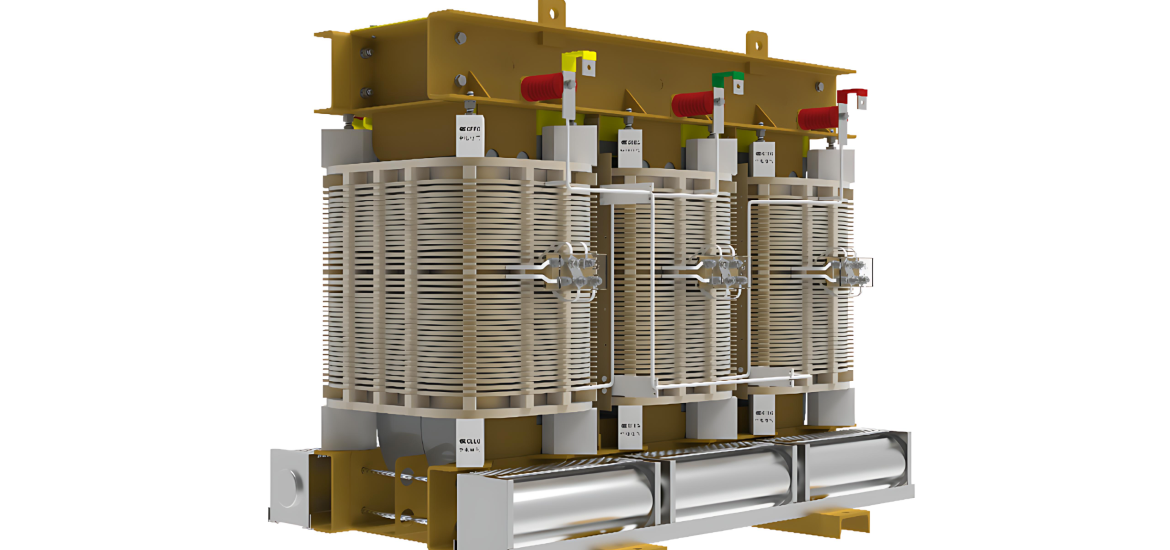

With the increase in need for electrical equipment worldwide and most major manufacturers quoting lead times varying from twelve months up to three years, utilities and industrial companies must find alternative transformer suppliers, other than those on the beaten track from Europe or the Far East, namely South Korea and Japan.

With many companies reluctant to try any new suppliers, especially countries like China, the technical staff must do detailed factory audits to satisfy the management of the utilities that this long-term investment with a different supplier is worth the money to be invested as the cost is too high to be written of as a bad experience.

As power transformers are a critical and a bespoke component and represent a significant capital investment for any other end user or utility, end users should ensure a detailed Factory Audit of prospective manufacturers are performed.

The overall transformer cost of ownership can significantly exceed the initial purchase costs when the total costs involved in the procurement, installation, commissioning, maintenance, and operation are accounted for. If or when something goes wrong with a transformer, either during the project phase or during in service operations, significant budget over-runs or revenue loss can result. This is the primary reason that most critical transformers receive some sort of additional surveillance by the end user, often in the form of design reviews and in-factory inspections.

To get new suppliers, a survey of transformer suppliers is performed on LinkedIn, the Internet and through Cigre and Industry experts. A shortlist is drawn up based on the overall impressions of the various specialists and these companies are then approached with the intention to perform a detailed survey of the companies’ products, facilities and systems, including their people.

As the supplier will most likely only provide a one-sided view of the quality of their product and the standard of their manufacturing, a full list of customers is requested. These customers need to be in areas designated in the detailed technical specification as being acceptable, e.g. China, EU Countries etc. This list of customers’ needs to include email addresses, contact persons and telephone numbers.

The customers are contacted with a list of questions to get their point of view on the company intended, their products, personnel, support and delivery times. The answers from the various companies are compared to decide on progressing with the supplier or not. Below is an extract of required service experience for transformer manufacturers.

Scope and Experience The Contractor shall comply with each of (1), (2a), (2b), (4), (5) and (6) below. Note point (3) may be considered by the Employer as alternative to (2a) and /or (2b).

At least 10 years’ experience in the production of HV and EHV Power Transformers in the voltage range as specified

Satisfactory1 Service experience of HV and EHV Power Transformers, in the voltage range as specified and higher;

in at least three Utilities in EU, UK, US/Canadian, Norway, Switzerland, Japan, Australia, South Korea or Middle East with proof of service experience in writing from these Utilities and acceptance of these by the Employer and

with a minimum of 20 units in total in these Utilities EACH of which shall have a minimum of f ive years satisfactory service experience at date of this enquiry issue and a minimum of ten of these transformers shall be single phase units. Relevant service experience in Irish and other Utility experience not referenced in tender submission may be used by the Employer in the evaluation of this criterion at their discretion

As an alternative to such experience of 2(b) above, similar experience in three Utilities in countries not named in Clause 2(a) above would be considered subject to proof of service experience in writing from these Utilities and acceptance of these by the Employer.

At least 5 years production in the particular manufacturing plant proposed is required, although if the particular plant proposed is a relocated existing plant using substantially the same workforce the combined time of both plants would be considered.

The transformers on offer in compliance with this specification shall be manufactured in the same plants which produced the products cited as meeting the service experience requirements outlined in (2) or (3) above.

Acceptance of any factory listed during the Tendering Process shall be subject to a detailed Factory Quality and Production Audit by the Employer.

The Contractor shall provide reliability/ MTBF statistics for their transformers per CIGRE TB642 Transformer Reliability Survey WG A2.37.

As power transformers are a critical and a bespoke component and represent a significant capital investment for any other end user or utility, end users should ensure a detailed Factory Audit of prospective manufacturers are performed. 1 Satisfactory service experience defined whereby there has been no major failures requiring an unscheduled outage of the HV Transformer for repairs occurring throughout the defined period of five years Once potential suppliers are selected, the next step is:

Factory inspections are performed to demonstrate compliance with the customer specification and to assess the overall quality (and indirectly the reliability) of the transformer under construction. The benefits from factory inspections are difficult to quantify in terms of money, but generally the avoided costs associated with the mitigation of potential problems that will surface during factory testing, installation, or operation are far greater than the relative minor expense incurred for the factory inspections.

But, before the actual on-site Factory visit is arranged, a process of evalua tion is followed to determine whether this company meets international quality requirements like ISO 9001, ISO 14001 or ISO 27001 standards, manufacturing and testing to IEC or other required standards.

In the questionnaire sent out before, details need to be provided on the management of the company, their financial state, documentation and quality procedures and much more. A detailed appendix is sup plied at the end of this article. Once the documentation is in place, the Factory Audit are arranged. An agenda is supplied to manage ment of the factory of what is expected during this visit and expectations from the potential client as to standards of production and more If or when something goes wrong with a transformer, either during the project phase or during in-service operations, significant budget over-runs or revenue loss can result. During this visit every section of the factory is visited. In the case where components are manufactured off-site, those facilities also need to be visited and the same process as for the main factory followed.

A general walk-through is conducted to get an overall impression of the factory, manufacturing conditions and staffing.

Management /Team leaders of every section/division are met, and input are requested from every staff member as to their training /understanding of the process, procedures tasks. Design reviews are performed to ensure the transformer design is suitable for its intended service. The design review is also used as a method to determine the technical team’s knowledge and know-how. How this review is handled is indicating how any future communi-cation and interaction would be handled.

During this visit documentation are checked, goods receiving, painting processes and overall standard of documentation. The testing facilities are also verified, as a manufacturer can quote on a transformer and when factory testing start, they may not be able to achieve the required test values. Proof of equipment calibrations and equipment registers must also be shown. Transport of completed equipment needs to be verified as the situation can arise that once the design is fully complete that the transformer size is too heavy or too wide for local roads, delivery to the closest port, if a long distance away may delay delivery and also alternative delivery routes in case of wars, e.g. Suez Canal blocked due to an ongoing war.

Staff technical capabilities during installation and the ability to com municate in the local language needs to be verified as well as the right to travel, i.e. valid passports. Does the company have a local partner or local capability to perform tasks like installation, transport of equipment and compliance with local safety regulations. If the company are found to be suitable, they will be advised to register and be asked to tender. In order to ensure that the product to be delivered, regular factory visits are scheduled to control the standard of manufacture, production and testing. Especially for a first off from a new factory it needs to be done on a very regular basis. Good control will result in an on-time quality product delivered, installed and eventually energised. Good control will result in an on-time quality product delivered, installed and eventually energised. Appendix A

Before the Factory audit commences the following set of documents are requested from a prospective supplier:

Manufacturer QA Questionnaire – details of the QA procedures utilised to be supplied

Company Profile – full company profile including location, strength and history

Organizational Charts showing VEO and all critical management functions

Key Personnel CV’s

Technical Team CVs

Financial Documents

National Industrial License

Evidence of frontline Staff Training

Company Insurance Certificate

Quality & Procedures Manual

ISO 9001:2015 Certificate

ISO 45001:2018 / OHSAS 18001:2007 certification (Occupational Health & Safety)

ISO 14001:2015 Certificate (Environmental Management System)

Vendor (Suppliers) Assessment and Selection Process

List of Raw Materials, Suppliers and Place of Manufacture

Work Instruction/process for Raw Materials Receiving, Inspection, Storing, handling & Issuing

Sample Raw Materials Test Reports

Sample of Manufacturing plan

Production Process Chart

Quality Procedure for In-process Inspection and Testing

Identification and Traceability Procedure

Sample of Traceability Record

Sample Routine Factory Test Report

Packaging and Shipping

List of Machines, equipment, and testing instrument

Equipment Calibration plan & Records

Machines Operating Instructions and Maintenance Records

Summary of System Type Tests & Prequalification Test

Technical Report for Measuring of the air quality and noise intensity

Procedure for Technical Inquiries

Data Sheet & Drawing

Fault History – Sample of Products and Treatment

Most Recent Inspection Report from Accredited Body

Technical Assistance Agreement with third party (if Applicable)

Approvals / acceptance of products (International)

Reference List

HSE Sample Documents (Incident records, audits, TBT,..etc)

Commitment Letter – letter from the prospective manufacturer indicating their commitment to be part of the process and intention to manufacture the transformers in the event of successful award of Tender.

Evidence from clients of any achievement / appreciation.

Robert le Roux is an Electrical Specialist with a range of engineering skills and practical experience obtained internationally. He joined ESB International as a Resident Engineer in 2010 and is presently a Senior Specialist with the ESB International. Mr. le Roux has a track record working on large-scale FACTS, Power Plant and Civil Engineering projects. His ex perience spans all aspects of the project life cycle from design through to construction and operation. He has worked on projects for ESB EMP in Ireland and ESB International in Bahrain and Southern Africa. As part of his role, Mr. le Roux is responsible for techni cal support to all sections, Technical Tender evaluation and also to assist ESB Networks and ESB Generation with problem solving on HV equipment related problems. This article was originally published in the October 2025 issue of the Transformer Technology magazine, which you can access here.

To download the PDF version of this article, click here.

This article was originally published in the October 2025 issue of the Advanced Insulation Soulutions: Condition Monitoring for a Safer Grid magazine.

View Magazine