1. Introduction

While reviewing an industry outlook report, I came across a striking projection: global electricity demand is expected to increase by a quarter by 2030 due to an increase in electric motors, electric heat pumps, electric vehicles, and AI applications, especially data centers. We have moved from just adding gigawatts (GW) to the grid to more complex requirements, such as decentralization, growing renewable integration, and grid digitalization. These requirements demand a resilient and future-ready grid. This reinforces my belief that, as energy players, we must focus on infrastructure that is adaptable, scalable, and built to endure the demands and regulations of tomorrow.

In the Middle East, the energy sector is experiencing unprecedented transitions, propelled by strong tailwinds of policy shifts, technological advancements, and sustainability goals. The rapid growth in the market is testing the readiness of market players to respond with smart, future-ready energy solutions, particularly for transmission and distribution infrastructure (T&D).

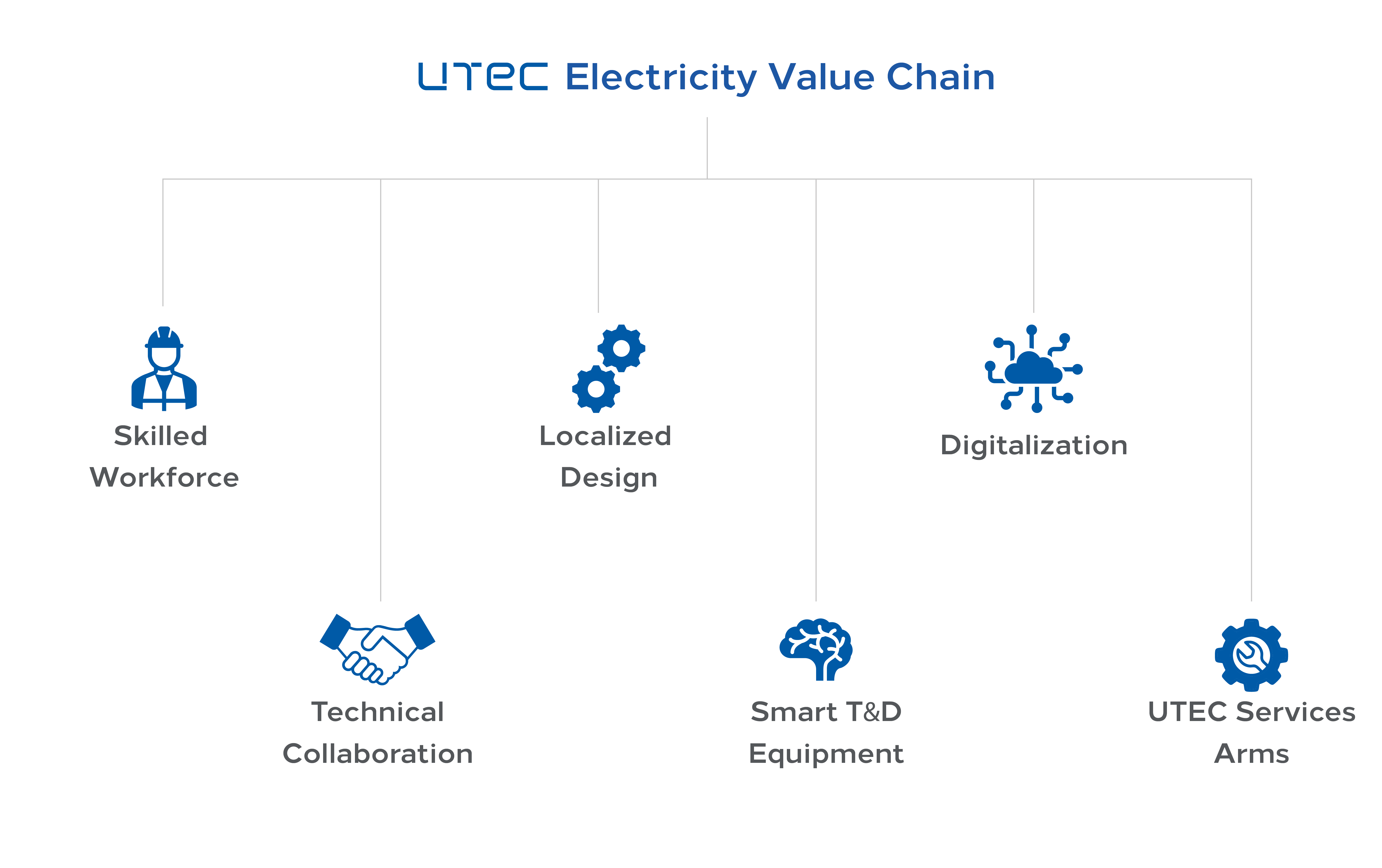

UTEC is answering the call by providing digital technologies and integrated services, positioning itself as a leader in building technology that meets the region’s evolving energy demands.

Today, I want to highlight the following,

- UTEC’s efforts in leveraging digital tools, local expertise, and fostering a service-focused model to support power infrastructure from installation to long-term performance.

- UTEC’s active participation in Saudi Arabia’s renewable energy and decarbonization efforts through its investment in the research and development (R&D) and manufacturing of different grid solutions, tailored to support the Kingdom’s Vision 2030 goals.

2. Driving Digital Transformation

At UTEC, digital transformation is the core of our strategy. By leveraging our intelligent technologies, we aim to enhance grid performance and optimize operations.

At the global stage, utilities are experiencing a shift toward decentralized networks. To achieve automation and grid flexibility, intelligent grid equipment like smart transformers, switchgear, and IoT-enabled platforms are essential. UTEC products feature real-time monitoring and remote control, which facilitates predictive and preventive maintenance. Here is how we have transformed our legacy products into comprehensive solutions:

2.1 Smart Transformers:

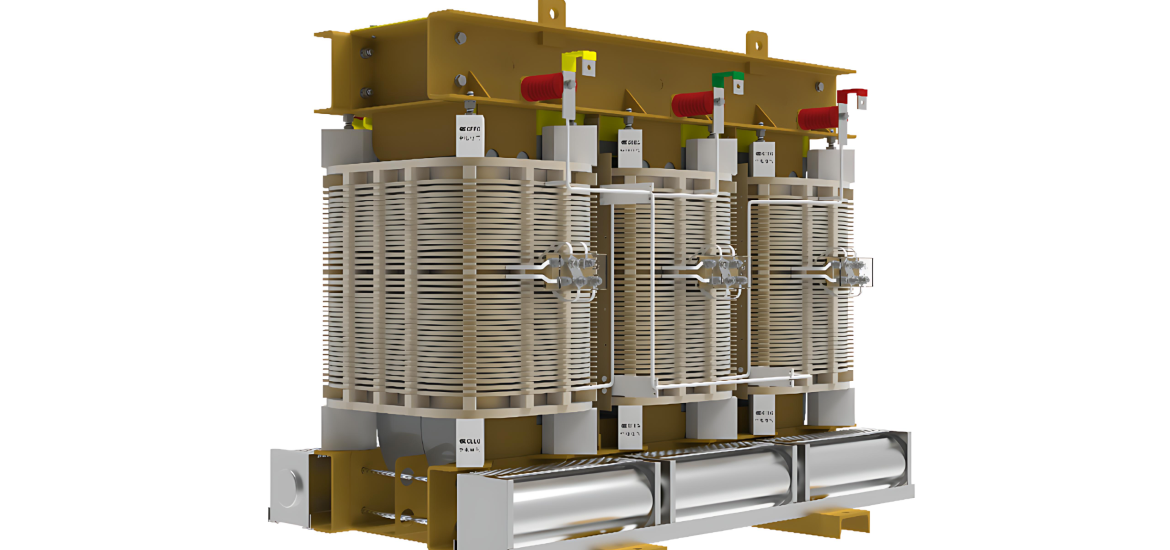

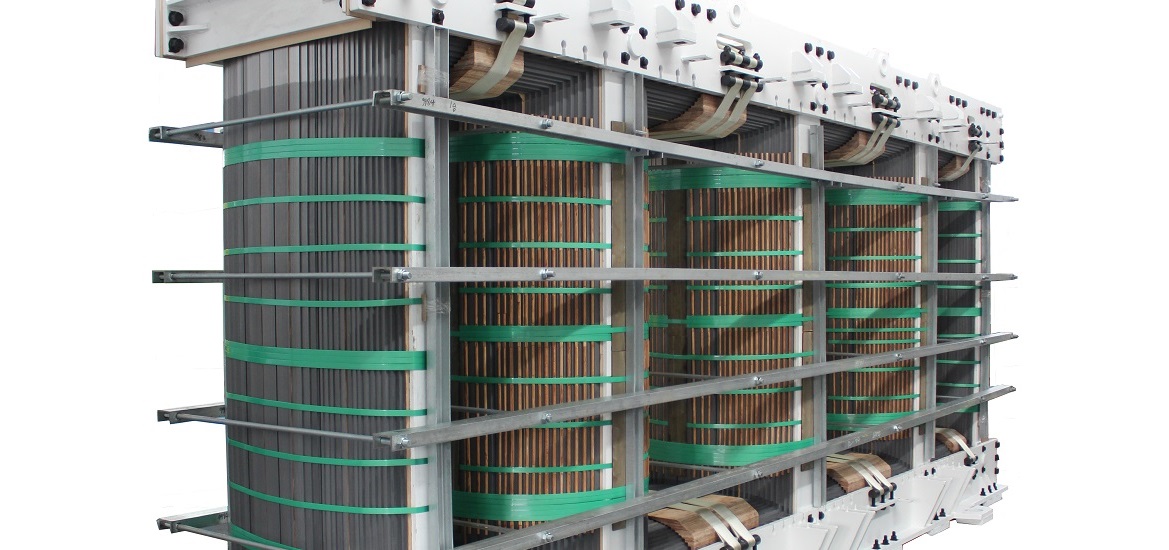

UTEC offers a range of transformers tailored to specific needs. What sets us apart is our ability to integrate innovative features into the transformer, designed to meet specific operational demands and asset health requirements. Mentioned below are two of our asset health management solutions:

- B100 Electronic Temperature Monitor (ETM) is an all-in-one solution that replaces traditional analog gauges, providing an accurate indication of problems within the transformer. It also enables the monitoring of essential transformer parameters, including oil and winding temperatures, as well as hydrogen levels.

- The Diagnostic Transformer Monitor (DM series) is a comprehensive, real-time monitor for detecting transformer health. It helps in identifying issues in bushings, windings, tap changers, and bus connections. These features help technicians and engineers perform predictive maintenance without outages by utilizing integrated partial discharge monitoring.

2.2 Smart Switchgear:

We are not only revolutionizing our transformers but also transforming our entire product portfolio, including switchgear.

Intelligent switchgear plays a pivotal role in modernizing power distribution. Our switchgear is equipped with sensors, communication modules, and data analytics, which enable real-time fault detection, remote operation, and predictive maintenance more easily.

- Comprehensive Switchgear Monitoring: The Smart Switchgear Monitor (SWGM) integrates high-speed waveform capture with both offline and online testing methods, enabling advanced and real-time monitoring. It performs analytics to detect operational issues before switchgear failure occurs.

- IoT Gateway Enablement: UTEC has made asset monitoring easy by utilizing a Serial Gateway IoT-enabled platform. Serial Gateway expands the use of the ConnectGrid smart infrastructure solution, enabling increased visibility of distribution systems at the grid edge.

The serial gateway is designed to be plug-and-play compatible with a wide range of sensors, including hydrogen, moisture, and SF6, thereby eliminating the need for unnecessary commissioning and setup.

2.3 Smart Ring Main Unit

Our cutting-edge Smart Ring Main Unit (SRMU) enhances the reliability and safety of power distribution systems. It caters to a broad spectrum of applications, including,

- Onshore/Offshore wind farms

- Photovoltaic power stations

- Small and medium voltage substations

- Industrial enterprise

- Large buildings

UTEC’s SRMUs are designed with precision and innovation. Our SF6 gas-insulated RMU EnerSwit empowers power distribution networks with unparalleled performance and resilience. EnerSwit is equipped with the following features,

- Metal-enclosed structure and a 17.5kV rated voltage.

- Equipped with a self-energized load switch and an ultra-low resistance vacuum circuit breaker.

- Fully interlocked operation with padlocking facility for maximum operator protection.

- Seamless integration with SCADA network for remote operation and control.

- Operates in different modes, including manual, electronic, remote, and through RTU.

3. Localization for Regional Resilience

Our support and focus on localization are primarily aimed at moving forward in line with Saudi Vision 2030 and the Kingdom’s energy sector development. The localization of technology has a positive impact on the growth of Saudi Arabia’s T&D market, as it promotes:

- Enhanced cost efficiency and pricing by reducing import tariffs.

- Accelerating lead times and operational efficiency.

- Tailored solutions for diverse applications.

UTEC offers a wide range of localized products, specifically engineered to meet the unique environmental, operational, and regulatory needs of the region:

- Distribution Transformers ranging from 50 KVA to 10,000 KVA.

- MV and LV switchgear, including the locally manufactured GearAir, a flagship MV switchgear, the PIX50, EnerSwit, and the smart RMU.

- Packaged substations, unit substations, and Solar substations

- Modular data center solutions

Our localization policy aligns with the Kingdom’s Local Content vision by enhancing local value creation, prioritizing domestic production, and investing in the research and development of essential equipment.

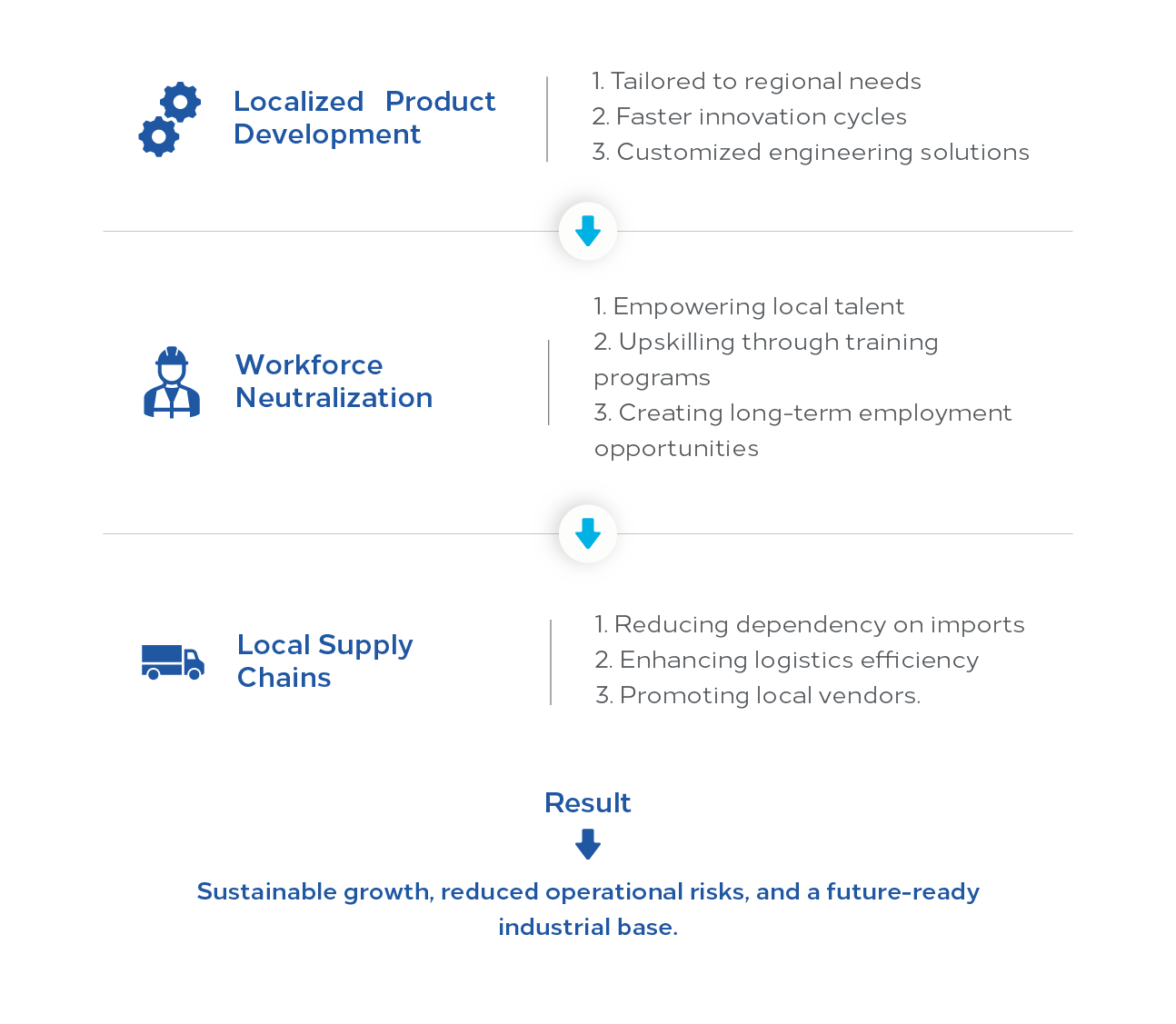

3.1 Three Pillars Approach

To foster resilience, support the local economy, and deliver long-term value to our customers, we rely on the Three Pillars approach. UTEC’s Three Pillars Approach focuses on localized product development, workforce naturalization, and strengthening local supply chains. Together, these pillars drive sustainable growth and deepen UTEC’s integration within the communities it serves.

4. Evolving Services Beyond Manufacturing

Our expertise goes beyond technology manufacturing. UTEC offers a suite of services curated to target preventive/predictive maintenance and asset management. UTEC’s service arms provide the following services:

- Installation and commissioning services

- Maintenance services

- Electrical system upgrade services

- Electrical engineering services

- Monitoring services

UTEC has been steadily expanding its services portfolio to move beyond traditional manufacturing and deliver greater value across the asset lifecycle.

5. Conclusion

In my opinion, the power infrastructure of the Middle East requires more than just innovation. It requires localization, region-specific solutions, and a long-term service commitment.

As the grid evolves, our focus remains clear: to empower our teams, deepen strategic partnerships, and continually adapt our offerings to shape a smarter, more resilient power ecosystem for the region. I see this as not just a strategic imperative, but a responsibility to ensure our actions today lay the groundwork for a sustainable energy future.

Wael Gad is the CEO and Board Member of Bawan Engineering Group, a subsidiary of Bawan Holding, a publicly listed KSA company. Bawan Engineering Group consists of several companies operating in the manufacturing and services of Electrical & Digitization equipment (Transformers, Substations, Switchgears, e-houses, Battery Energy Storage Systems (BESS), and Data Centers). Bawan Engineering Group sells its products in more than 20 countries across the world under the brand UTEC.

Wael has more than 30 years of diversified experience across Europe, the Middle East, and Africa, leading several multinationals and regional organizations. Wael serves as a board Member of several companies in Saudi & Egypt. He also served as an advisory board director and as a Business Development and governance Advisor with several organizations.

Previously, Wael was the CEO of Philips Lighting in Saudi Arabia, the General Manager of Microsoft MMD in Saudi & Yemen, and he also held several C-level assignments for Electrolux across EMEA.