Robert Vary, CEO and President of Reinhausen Manufacturing USA, explains the background and benefits of the modular system solution for monitoring, con trolling, regulating and digitizing power transformers.

Where do you see the biggest challenges for grid operators and utilities in the USA?

On the one hand, there is the energy transition and the associated electri f ication of the economy. The grid needs to be expanded at all levels to achieve this, yet longer delivery times for transformers–potentially up to five years complicate the necessary updates. The situation is being exacerbated by new super consumers such as AI data centers. For example, in Virginia, by far the most important region for data centers, electricity consumption is set to more than double in the next ten years. The industry is also experiencing an outflow of expertise due to an aging workforce. Last but not least, cost pressure is growing, which is bringing operating and maintenance costs into focus.

How can Reinhausen help in the face of these challenges?

With the new ETOS® MD-IV, we offer a solution to many of these require ments. Because we understand the struggles faced in the US market, our im proved motor drive for on-load tap-changers now comes with ETOS® (Embedded Transformer Operating System) included. ETOS® is an open and modular system solution for monitoring, controlling, regulating and digitizing power transformers. It is the world’s first open operating system for intelligent trans formers.

What are the specific advantages of ETOS® MD-IV for operators?

ETOS® MD-IV is more than just a motor drive for on-load tap-changers. You can now equip transformers with sensors from all manufacturers. All the information comes together in the ETOS® control cabinet and is evaluated by algorithms. The algorithms capitalize on Reinhausen’s data and experience from many decades of working with transformers. That data then enables analysis so that maintenance intervals can be optimized, service life extended and capacities optimized. What’s more, operators become less dependent on the expertise of their employees as they continue to develop the next generation workforce.

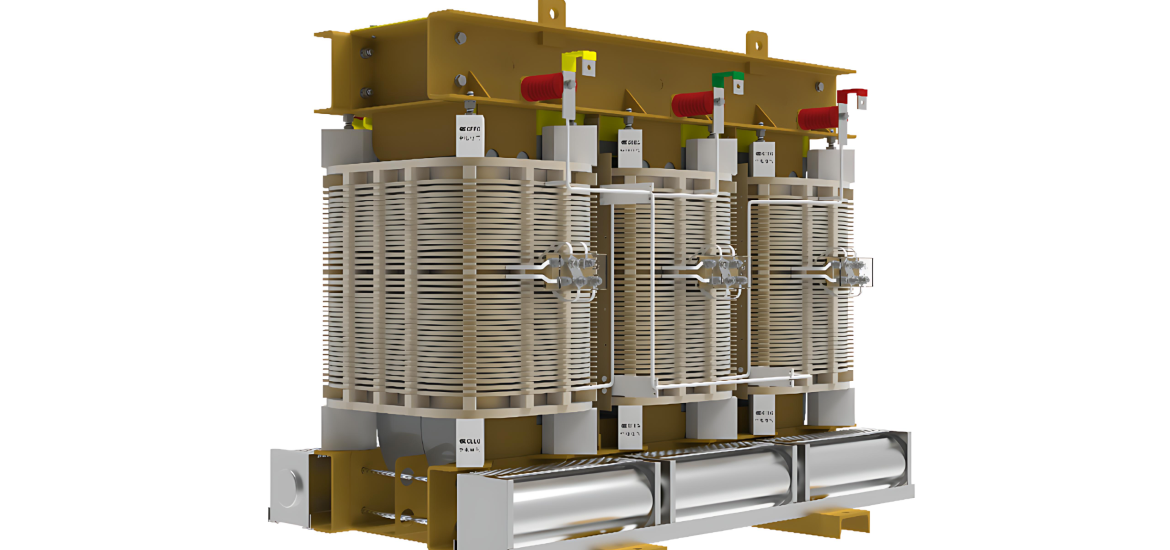

ETOS® MD-IV

Monitoring. Regulation. Control.

With the fourth generation of the MD motor-drive, customers now have the option of combining the classic drive function used from TAPMOTION® MD-III with ETOS® functions (Monitoring, Regulation & Control). The additional func tions can be installed modularly and cost-effectively in the cabinet.

Data aggregation through the connection of sensors and actors

At the heart of the power transformer lies the process level, encompassing the physical components which also enables the voltage conversion from one level to another. On this level there are sensors (conventional and intelligent), protection accessories and actors (OLTC and cooling system). These are in physical contact with the transformer.

Serving as the interface between the physical process and the control systems, the field level integrates sensor data to monitor the transformer’s condition and actuator signals to regulate its operation. A key enabler in this domain is ETOS®, which plays a central role in the global shift toward advanced transformer monitoring. According to IEEE PC57.143/D21, transformer failure rates can be reduced by up to 72% through a combination of online and offline monitoring, underscoring the significant benefits of this approach.

Online condition assessment using advanced analytics

ETOS® plays a pivotal role, gathering online data from various sensors and applying algorithms to analyze and interpret it as well as ensuring an effi cient control of the temperature and the voltage. To suit different utility requirements, it supports the modular integration of functions in the areas of control, regulation, monitoring, and the tap-changer drive. By seamlessly integrating sensors, various communication options, and advanced analytics, ETOS® provides its real-time condition and performance. This empowers oper ators with deep insights, enabling smarter decisions around maintenance, optimization, and asset management.

How to transition to predictive maintenance strategies

While ETOS® provides comprehen sive monitoring and control for individual transformers, this may not be sufficient for utilities that operate entire transformer fleets. When it comes to comparing the condition of multiple transformers, an essential requirement for condition-based or predictive maintenance strategies, a centralized overview of all asset-related online and offline data becomes crucial. This is where Asset Performance Manage ment (APM) systems come into play.

Unlike SCADA systems, which require bidirectional communication to control assets (e.g., switching on fans), APM systems operate with unidirectional data flow, receiving condition data from substation assets without sending commands. This architecture eliminates the risk of third-party interference. While SCADA systems often rely on hardwired connections due to their critical nature, APM systems can be securely connected via LTE modems, which eases installation efforts in the field. MR’s APM solution, TESSA® APM, enables the integration of transformers as well as other key substation assets, providing a secure and centralized platform for fleet-wide asset monitoring and strategic decision-making.

The benefits of integrating essential control functions

In addition to its wide range of online monitoring capabilities, ETOS® also integrates essential control functions such as cooling control and automatic voltage regulation. This means that functionalities traditionally handled by separate stand-alone devices can now be embedded directly into the modular ETOS® system. While the functionality remains unchanged, this integration brings several significant advantages:

- Cost Savings

By integrating voltage regulation and cooling control into ETOS® MD-IV, the need for separate hardware is eliminated. The system shares the same housing, CPU, and display, significantly reducing manufacturing costs.

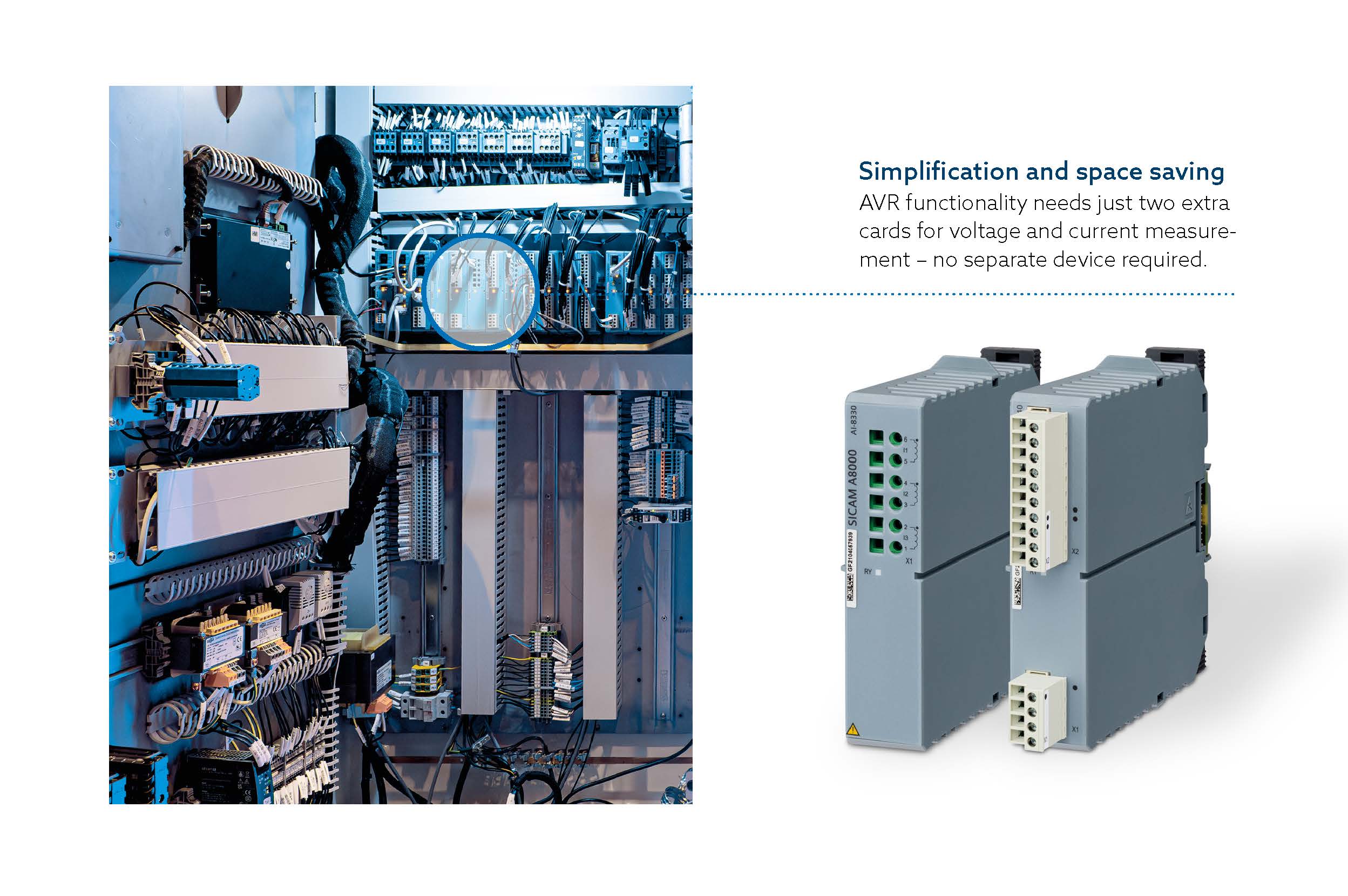

- Space Savings

Multiple functions are consolidated within a single cabinet, minimizing the control cabinet footprint up to 65% and freeing up space for other components.

- Reduced Wiring and Cabling Effort

With Automatic voltage regulation (AVR) and monitoring systems co-located, input signals (e.g. from VTs and CTs) can be shared across functions. A single SCADA connection further simplifies installation and reduces cabling time.

- Convenient Access

ETOS® MD-IV features a unified, web-based software platform for intuitive operation and monitoring — accessible from anywhere.

- Lower System Complexity

Fewer interfaces and devices mean less data entry, reduced vendor coordination, and faster commissioning. This also simplifies ongoing maintenance.

By integrating control functions such as voltage regulation and cooling control into ETOS®, utilities benefit from reduced hardware requirements, lower system complexity, and streamlined installation. This leads to significant cost savings and enables intuitive, centralized operation through a single platform – ETOS®.

Beyond the hardware-related benefits of functional integration, ETOS® also delivers added value through its innovative voltage regulation functionality. As the share of renewable energy sources continues to grow, voltage regulation is becoming increasingly complex — and ETOS® is designed to meet these evolving challenges with smart features that make the transition as seamless as possible for utilities.

How renewables are changing automatic voltage regulation

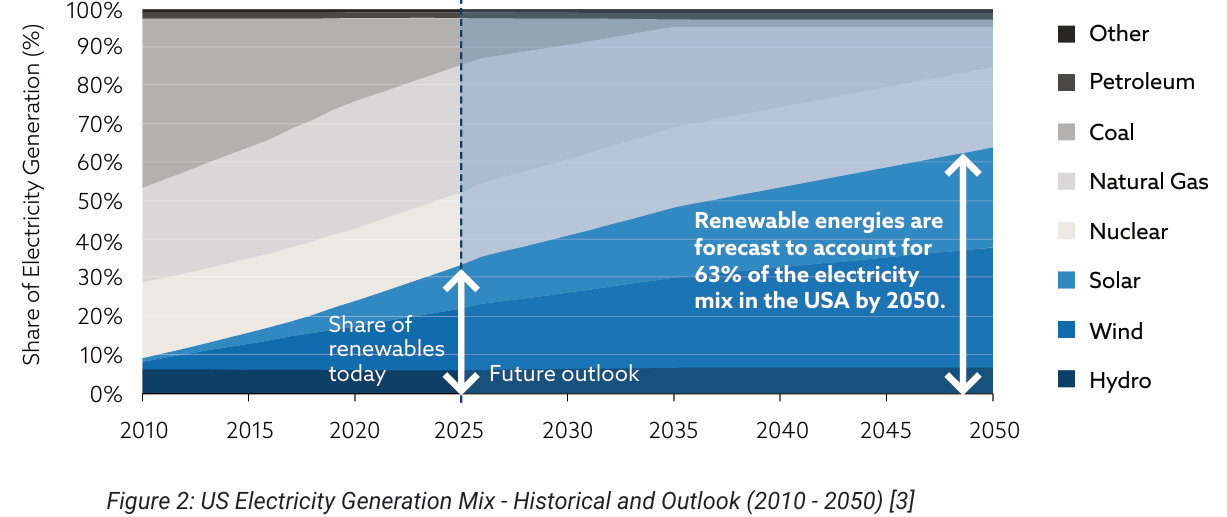

The United States has experienced a rapid expansion in renewable energy capacity. As of 2025, renewables account for over 25% of the country’s elec tricity generation, with wind and solar leading the transition. This growth is largely driven by federal incentives and state-level mandates [1][2]. In contrast, Germany has already surpassed the 50% mark in renewable electricity genera tion, with some days reaching nearly 100% due to high wind and solar output [1]. This contrast highlights a key challenge: while both countries are integrating renewables, Germany’s higher penetration has already exposed the limitations of traditional grid control systems. These experiences offer valuable lessons for other nations navigating similar transitions [2]

In conventional power systems, voltage regulation was relatively straightforward: Power generation was centralized, with large thermal or hydro plants feeding electricity into the grid at the highest voltage levels. Voltage deviations were primarily caused by changing loads, not generation. Because load patterns followed predictable daily and seasonal trends, AVR setpoints could be adjusted at fixed times. This system worked well in a world of stable generation. Renewables disrupt this model in several ways. Solar panels on roof tops and wind turbines in rural areas feed power into lower voltage levels of the grid. This decentralization introduces voltage variability at multiple points in the electrical grid. Unlike predictable load patterns, renewable generation is volatile and driven by weather conditions, thus making fixed time setpoint adjustments increasingly difficult. If AVR systems continue to operate on fixed schedules, they may fail to respond to real-time fluctuations, which increase the risk of voltage band violations. Depending on the amount of renewable energy fed into the LV side of the transformer, the effective voltage drop across the network will change. In times of high renewable feed-in, even reverse power flow can occur at some substations in the grid. If the setpoints remain constant regardless of the renewable infeed, the voltage will fluctuate at the feed-in points of the grid.

The limits of line drop compensation

One traditional method to address this challenge is line drop compensation (LDC), which dynamically adjusts the voltage setpoint based on the calculated voltage drop along a distribution line. The calculation is based on load current, resistance and reactance of the line. While effective in simpler grid configurations, LDC faces significant limitations in modern, decentralized networks. In complex grids we can have consumers, prosumers or even renewables connected at various distances along the line. As a result, LDC is only accurate for specific sections of the grid. To maintain voltage within permissible limits across all nodes, operators often rely on averaged parameters to derive a setpoint that works broadly. The situation is further exacerbated by the rapid expansion of renewable energy installations, particularly rooftop solar, at the distribution level. This growth frequently outpaces the physical expansion or reinforcement of grid infrastructure. In rural and suburban networks with high solar penetration, maintaining voltage stability becomes increasingly difficult, especially during peak generation periods when reverse power flows and local overvoltages are more likely to occur.

Making sure that the voltage remains inside the permissible bandwidth

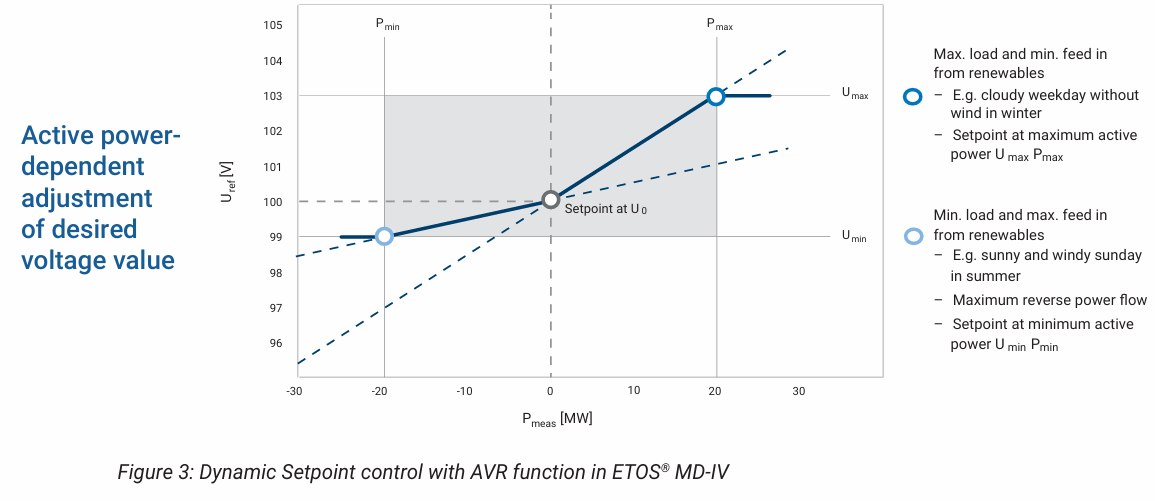

To maintain the voltage within permissible bands, grid expansion is inevitable. However, since this can take a long time to accomplish, complementary tools are required to help manage the grid more flexibly and cost-effectively in the short to medium term. One innovative measure is the load flow-dependent regulation of voltage at the substation level. This approach dynamically adjusts the voltage setpoint based on real-time active power flow conditions, helping to stabilize voltage levels in the medium-voltage grid. Here’s how it works:

- Load flow simulations are conducted to determine the required voltage setpoints at both minimum and maximum active power flows as well as under no load.

- These simulations also consider extreme load scenarios (both high and low), as they influence voltage drops or rises along the line.

- The goal is to find a setpoint characteristic that ensures voltage remains within the allowed bandwidth under all conditions and at all points of the line.

- Based on these simulations, a dynamic setpoint curve is developed, allowing the AVR to adjust in real time depending on the actual power flow.

This method ensures that the voltage remains inside the bandwidth at every point in the grid, even under reverse power flow with volatile renewable feedin and load variability. In MR’s TAPCON® products as well as ETOS® MD-IV this function is available as a standard TAPCON® Dynamic Setpoint Control (TDSC).

In an increasingly decentralized energy landscape, dynamic setpoint selection based on real-time load flow offers a practical and forward-looking solution. It enables grid operators to maintain voltage stability efficiently, even under volatile renewable feed-in conditions—bridging the gap until long-term grid expansion measures are in place.

ETOS® MD-IV: Securing the future of grid operations

With ETOS® MD-IV, utilities gain a scalable and future-ready solution that adapts to the evolving demands of modern power grids. Its modular design, intelligent analytics, and integrated control functions empower operators to maintain voltage stability. Furthermore, this carries the additional benefit of reduced operational costs and extended asset lifecycles. As the energy transition accelerates, ETOS® MD-IV provides the tools utilities need to manage complexity, ensure reliability, and make smarter, data-driven decisions—today and into the future.

Konstantin Ferstl

Portfolio Manager

Voltage Regulation and Thermal Monitoring

References

[1] IRENA (2025), Renewable Energy Statistics 2025

[2] KPMG (2025), US Renewable Energy Outlook 2025

[3] U.S. Energy Information Administration (2025), Annual Energy Outlook 2025

Johannes Maihöfner

Project Manager

Motor Drive ETOS® MD-IV

Maschinenfabrik Reinhausen

Falkensteinstraße 8

93059 Regensburg

Germany

This article was originally published in the October 2025 issue of the Advanced Insulation Soulutions: Condition Monitoring for a Safer Grid magazine.

View Magazine