Digital Twins Applied to Power Transformers

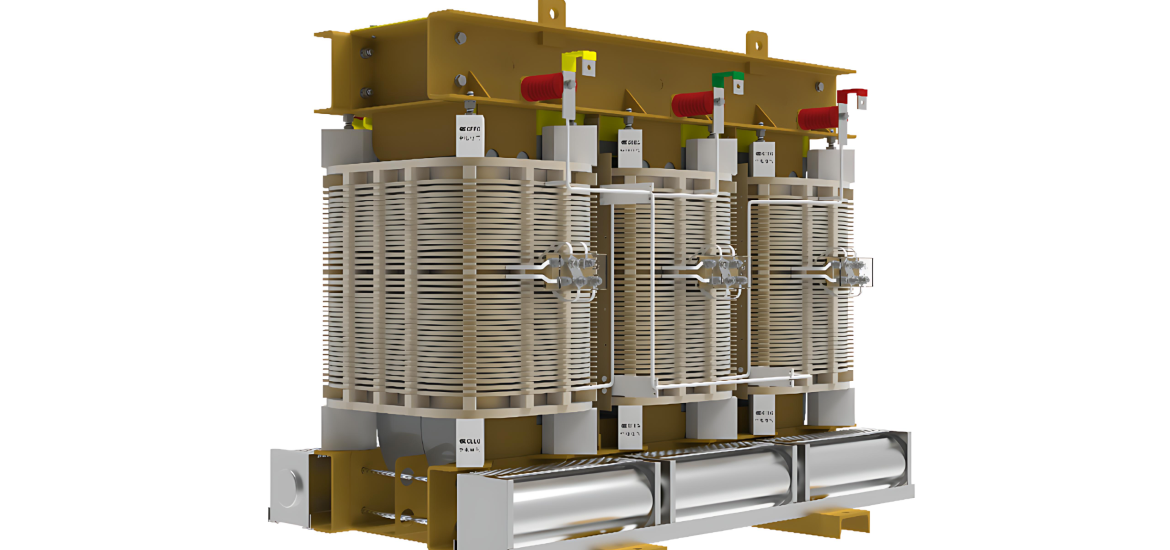

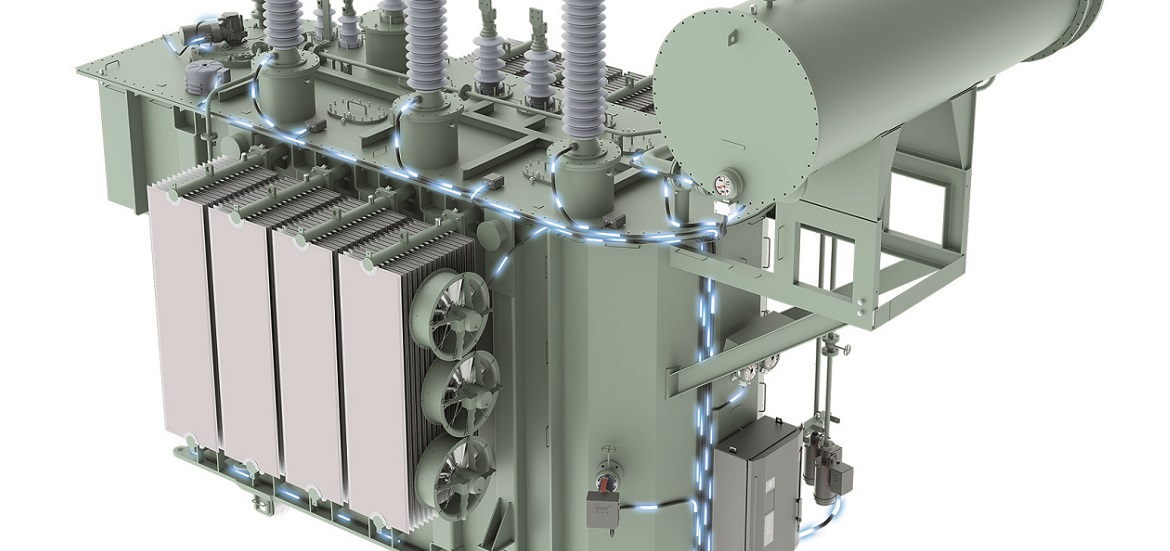

The concept of Digital Twins, a technology developed by the NASA, is being transposed to various fields in recent years. Digital twins (DT) represent a highly promising technological approach for complex assets such as power transformers. DT provide a detailed, dynamic virtual representation of physical assets, enabling simulations, condition assessments, predictive and prescriptive analyses. The applications of digital twins in the context of power transformers are manifold. The perspective we present covers at a high level three types of digital twins: the prototype (DTP), covering the design phase; the instance (DTI), covering the manufacturing phase; and finally, the aggregate (DTA), covering the operations phase. Predictive analysis using artificial intelligence (AI), combined with condition assessment at the component level, can extend the life of an asset by managing risk, thus supporting sustainable development objectives. During the design phase, the digital twins can simulate and test various design scenarios in a virtual environment. This enables engineers to optimize transformer design in terms of performance, reliability, and efficiency before manufacturing begins. By analyzing the various design parameters and their impact on transformer performance, potential problems can be identified and mitigated early in the process. Relying on physics-based models, data-based models, or a combination of both (hybrid models), engineers can predict how transformers behave by modifying design parameters, environmental conditions, and operational constraints. This ability to model and simulate, considering electromagnetic aspects, thermal dynamics, and mechanical integrity, enables designers to take more informed decisions. The manufacturing phase involves integrating various components and systems into the transformer. Digital twins can help plan and simulate the assembly process, identifying potential bottlenecks or challenges in the workflow. DT enable engineers to understand how different components interact and function in the system. This allows integration problems to be identified quickly, reducing the risk of delays and the additional costs associated with rework. Digital twins can document transformer assembly processes, becoming a digital thread that records each validation step and associated information and make available all reference documents, such as assembly drawings and procedures. Digital twins can also train transformer assembly and maintenance personnel in a virtual environment, familiarizing them with the transformer’s design, fabrication, and maintenance activities.

Once the transformer is operating, digital twins become essential for optimizing maintenance activities and reliability. For example, a digital twin can track component changes, assess their condition by applying degradation algorithms, perform predictive and prescriptive analyses, and integrate artificial intelligence models. By combining operational, inspections, tests, and probes data, the digital twin can provide a detailed, up-to-date view of the transformer’s condition and of each of its components. It can reduce the impact of a component’s functional failure by anticipating it. Predictive analysis using artificial intelligence (AI), combined with condition assessment at the component level, can extend the life of an asset by managing risk, thus supporting sustainable development objectives. Digital twins enable design optimization, improved manufacturing processes, and operational reliability by providing a virtual counterpart that faithfully reflects the physical asset. In short, digital twins offer a dynamic approach to managing power transformers throughout their lifecycle. Digital twins enable design optimization, improved manufacturing processes, and operational reliability by providing a virtual counterpart that faithfully reflects the physical asset. Digital twins, which come in various use cases, represent a significant advance in asset management, stimulating innovation and contributing to power grids’ reliability and sustainability. By leveraging advanced AI techniques, synthetic data and condition assessments at the component level, it is possible to develop algorithms to improve power transformers’ reliability, efficiency, and maintenance strategies. DT can also be used for the analysis of contingencies and budget planning. Ongoing collaboration between AI researchers and transformer experts will be vital to unlocking the full potential of digital twins.

Digital twins, which enable the coexistence of deterministic (physics-based) artificial intelligence associated with expert systems and the results of probabilistic AI models, are set to accelerate our knowledge of power transformer behaviors and serve as a conceptual basis for the same developments for civil, electrical, and mechanical assets that make up an electrical network. Jean-Pierre Girard has over 35 years of experience in the electronic and electrical equipment field, with management responsibilities in application engineering, service, product safety, process improvement, quality management, and electronic business. He has acquired expertise in asset management applied to critical infrastructures and has been a speaker on this subject internationally. He worked at Siemens for 22 years and held several management positions. From 2001 to 2008, Mr. Girard was Executive Director responsible for Hydro-Québec and SNC-Lavalin, representing all Siemens business units. Mr. Girard was a member of the Board of Directors of the Quebec Electrical Industry Association. He has been involved internationally on numerous business committees and company-wide transformation initiatives. He is the founder of HEXACODE Solutions. (jpgirard@hexacode.ca) This article was originally published in the June 2024 issue of the Transformers Technology magazine, which you can access here .

To download the PDF version of this article, click here .

This article was originally published in the June 2024 issue of the Advanced Transformer Testing and Technologies magazine.

View Magazine