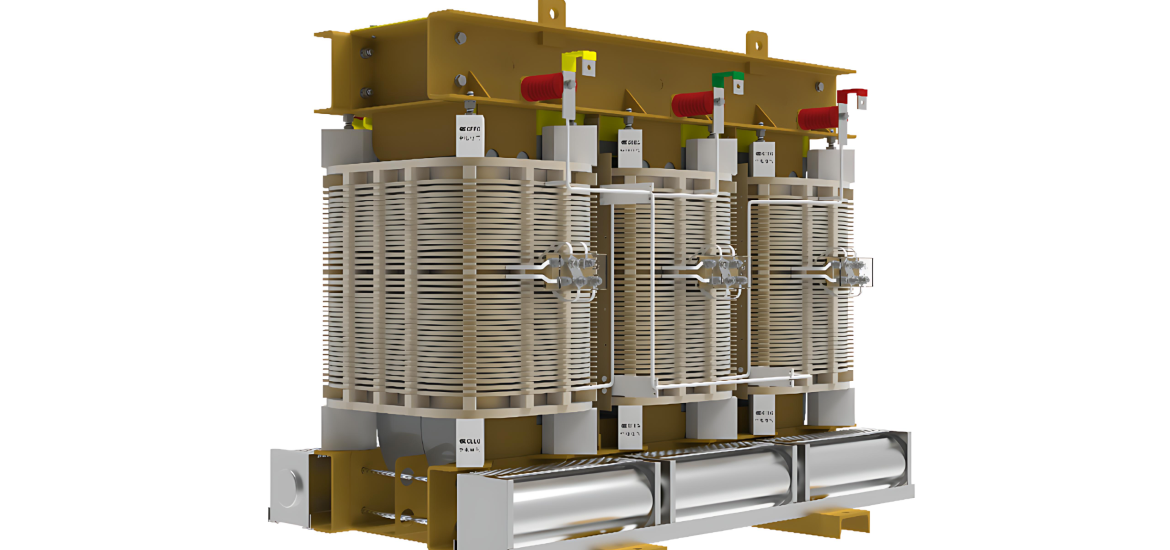

MEASURING TRANSFORMER TEMPERATURE

In the world of power distribution and electrical utilities, monitoring transformer temperatures is paramount for ensuring efficient and safe operation. Over the years, technology has evolved, offering more precise and reliable methods for temperature monitoring. This article explores three distinct approaches to this vital task: Traditional Temperature Gauges, Electronic Temperature Monitors, and Direct Measurement with Fiber Optic Temperature Probes. 1. Traditional Temperature Gauges

Oil Temperature Indicator (OTI) and Winding Temperature Indicator (WTI) Gauge technology was developed in the 1940s and was used to control the cooling system and provide indication of issues to give the transformer thermal protection. They are sufficiently rugged to be used for protection purposes if the recommended maintenance and/or calibration verification is carried out regularly.

However, there are some limitations to this method. Regular on-site maintenance must be scheduled to ensure relative accuracy. WTIs are prone to mechanical damage which may result in an inaccurate temperature reading which leads to inefficient cooling and tripping control. For a deeper understanding, download this white paper. 2. Electronic Temperature Monitors

Electronic Temperature Monitors (ETMs) can replace up to three analog gauges and consolidate temperature data and cooling control into a single point of communication. They provide better measurement accuracy than traditional gauges by using transformer design information to calculate winding hot spot temperature both during load fluctuations and steady conditions. ETMs connect to multiple bushing CTs so that all three phases are monitored with one device to identify which one is truly the hottest. Additionally, they calculate the insulation loss of life which helps utilities manage the estimated life of the transformer.

ETMs have electronic communication which provides the data to utilities remotely. It keeps detailed records of data so you are able to download history at any time. ETMs come in robust fail-safe designs to provide additional reliability beyond what a gauge can offer. ETMs come in robust fail-safe designs to provide additional reliability beyond what a gauge can offer.

3. Direct Measurement with Fiber Optic Temperature Probes

Fiber Optic Temperature Probes provide real-time direct winding monitoring. They help validate that the thermal model is truly doing what it is supposed to do. Probes are installed in the winding in a modified spacer. The tip is the measurement point which sends a light pulse signal down the fiber. The probe connects to a Transformer Monitor which communicates direct winding data back to the utility. The monitor also has the ability to model multiple windings. Fiber Optic Temperature Probes provide real-time direct winding monitoring. They help validate that the thermal model is truly doing what it is supposed to do. This option is great for critical transformers such as a bulk power transformer because the cost of adding fiber optic temperature probes is reasonable.

Tony Pink founded the North American division of Dynamic Ratings and has since assumed the global management role for the business. He is a recognized leader in electrical power asset control and monitoring solutions with over 20 years of experience in this niche. His professional career began in diesel powered generation equipment with paralleling switchgear design and construction. He then transitioned to SPX Transformer where he managed the Field Service business and subsequently assumed the sales management role for SPX aftermarket parts and service.

In 2002, Tony founded Dynamic Ratings, Inc. and built an outstanding team of industry expertise that is enabling utilities to build successful asset health management programs. This business goal was accelerated through the acquisition of Electrical Diagnostic Innovations in 2009 and the acquisition of the iBridge product line from Telkonet in 2011.

Tony served as the secretary on the first IEEE guide for monitoring power transformers (IEEE C57.143). He also serves on the University of Marquette Electrical and Electronics Industry Advisory board, helping to ensure the power industry has a continual flow of exceptional engineering talent. He holds a B.S. in Electrical Engineering from the Milwaukee School of Engineering and an MBA from Marquette University in Milwaukee. Share this article

This article was originally published in the October 2023 issue of the Bushings and Components magazine.

View Magazine