Transformer cooling control systems, sometimes called ETMs, are designed to maintain optimal operating temperatures by precisely regulating the cooling mechanisms. Strategically placed sensors monitor temperatures and other transformer parameters allowing the control system to determine the appropriate cooling response.

Power transformers are critical components in electrical grids worldwide, facilitating the transmission and distribution of electricity over long distances. These transformers are designed to handle large amounts of electrical power efficiently while minimizing losses. One crucial aspect of their design is the cooling system, which ensures optimal operating temperatures and extends the transformer’s lifespan. In this article, we will delve into liquid immersed power transformer cooling systems, exploring their types, mechanisms, and their importance in ensuring reliable electricity supply.

In today’s culture we find ourselves in a constant bombardment with the terms “innovative”, “ground breaking”, “state-of-the art” as we see updates within our respective industries. The power systems industry, being no exception to this, often leaves out the basic concepts regarding the functionality of our major equipment as new personnel come on board, change roles, or continue education and training. Power transformer basics have remained rather constant for many years now, being a critical and very costly asset in today’s power system but are rarely associated with the words “innovative” or “state-of-the art”. We often treat them as no more than another component on a diagram because a transformer is a transformer after all, right?

Importance of Cooling Systems

Power transformers generate heat during operation due to core losses (eddy currents and hysteresis) and winding losses (resistance in windings). Excessive heat can degrade insulation materials and shorten the transformer’s lifespan. Therefore, effective cooling is essential to maintain optimal operating temperatures and ensure reliable performance over the transformer’s operational life.

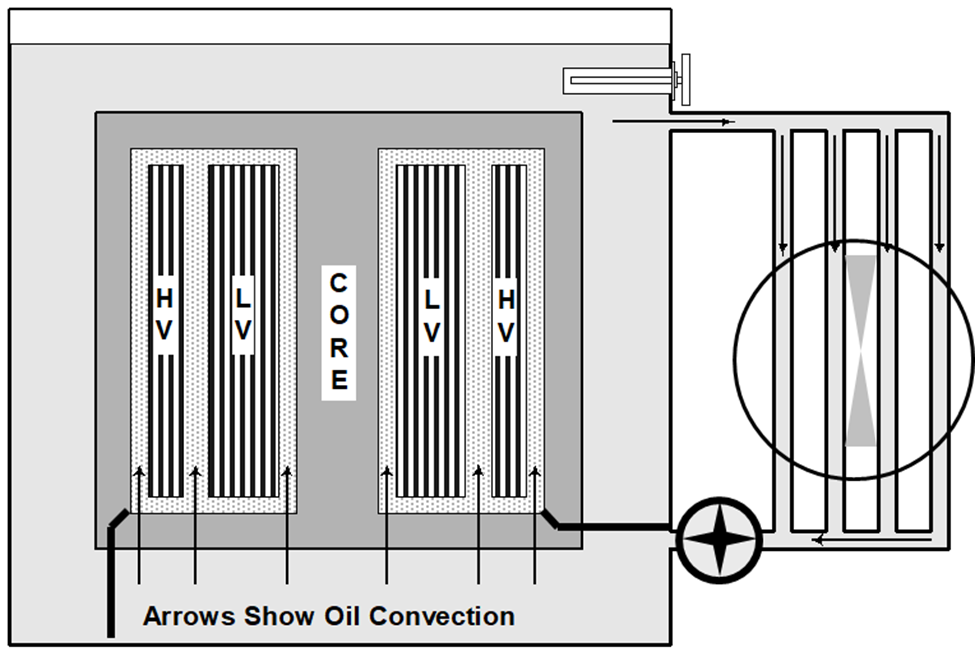

Liquid immersed power transformers are designed in such a way that the core and coil are immersed in a bath of transformer oil. The oil absorbs heat from the core and coil and then dissipates that heat through the tank wall and external cooling systems.

Ultimately, the loading capacity of a liquid filled transformer is dependent on the cooling capacity to ensure the transformer temperatures remain within design guidelines.

Common Power Transformer Cooling Types

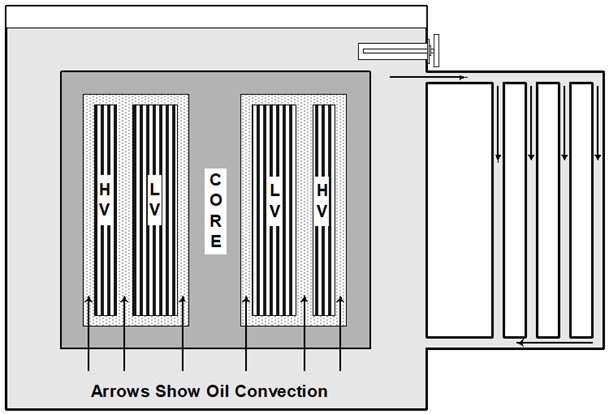

Natural Cooling (ON or ONAN)

The simplest form of cooling available in liquid immersed power transformers, this method simply relies on natural convection. This method can be classified in two different categories, but both rely on the same principle. Oil Natural (ON) simply identifies there is no external cooling present, and the oil simply dissipates the heat through the tank wall. Oil Natural/Air Natural (ONAN) includes the additional external cooling which is often the installation of radiators. Via natural convection the hot oil enters the radiators at the top port then falls downward in the radiators as the oil cools from air naturally passing along the radiator. The cooled oil then returns to the bottom of the main tank with a continuous convection cycle as seen in Figure 1.

Since this method relies on natural convection, there are no moving parts, noise pollution concerns or energy consumption and minimal maintenance items. But there are limitations, we are restrained by the amount of heat the oil can dissipate naturally which in turn limits the loading capability of the transformer (see Figure 1).

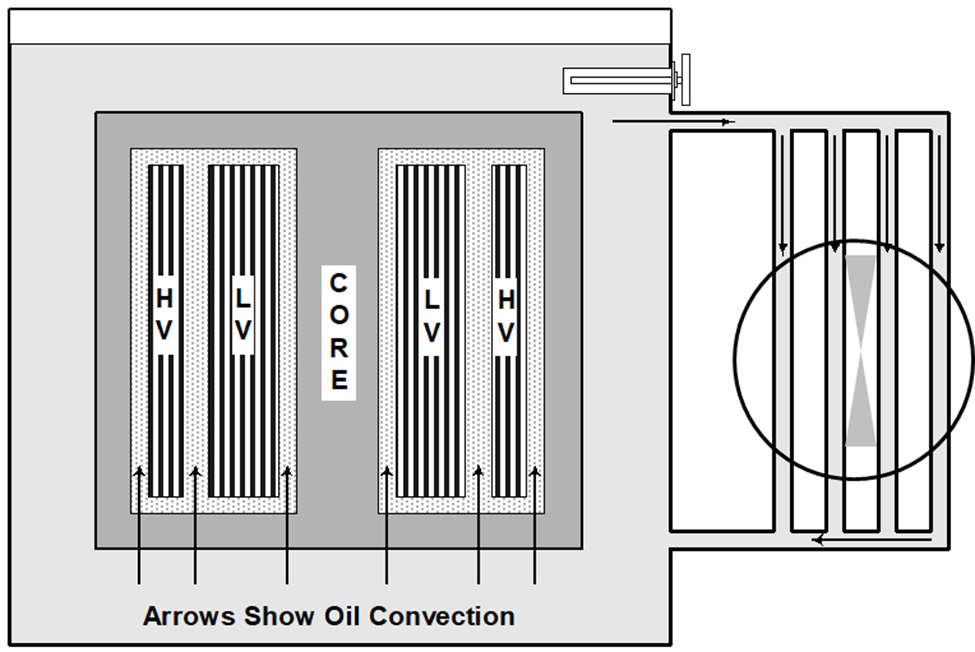

Oil Natural/Air Forced (ONAF)

Very similar to ONAN we have ONAF or Oil Natural, Air Forced which involves the characteristics an ONAN transformer, external radiators, but with the addition of cooling fans which increase the volume of air moving across the radiators’ surface therefore increasing the rate at which the radiators can dissipate the heat from the oil which in turn leads to an increase in the transformers thermal and loading capacity (see Figure 2).

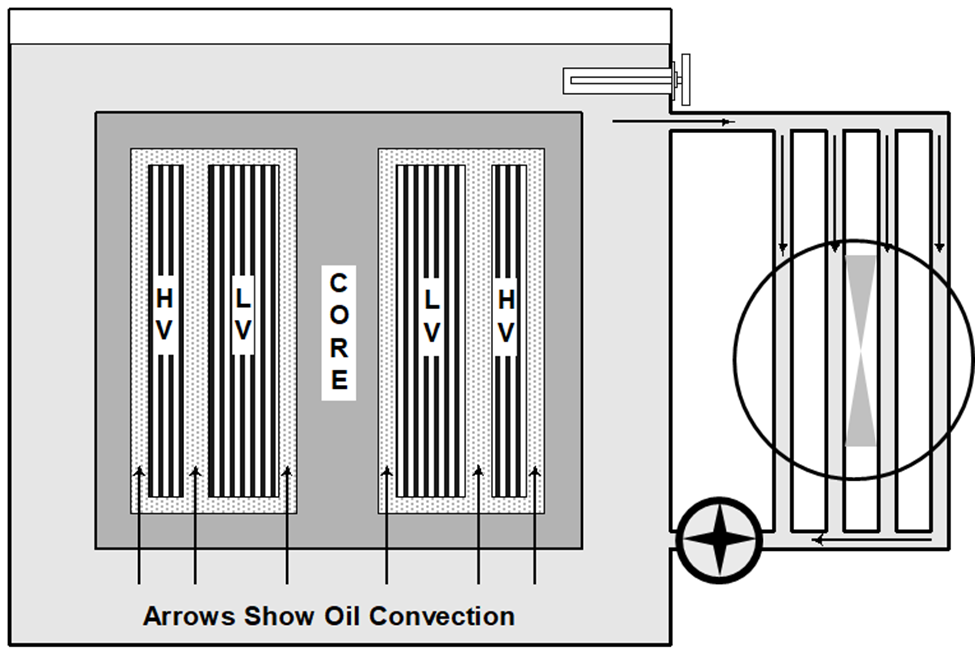

Oil Forced/Air Forced (OFAF)

Oil Forced, Air Forced, simply building off the two previously described methods with one addition. A pump is added to the cooling system to increase the circulation of oil though the transformer and external cooling system. In some applications of OFAF transformers, coolers are used in place of radiators and fans. These coolers are self-contained units which utilize fans, pumps and radiators to dissipate heat (see Figure 3).

Oil Directed/Air Forced (ODAF)

And finally, to build on the previously mentioned cooling types we land on Oil Directed/Air Forced (ODAF). This type Includes all the above-mentioned features of Oil Forced/Air Forced (OFAF) but additionally utilizes baffles within the transformer to direct the flow of the oil as it passes through the windings. This is often referred to as directed flow and indicates there is some form of control as to how the oil flows through the transformer tank, directing the oil the way in which it has the greatest impact in heat dissipation from the windings. Once again, furthering the transformers loading capabilities (see Figure 4).

It is important to note that most transformers will have multiple ratings that are a combination of different cooling types and operate in stages. Each stage of cooling that is implemented during operation allows for additional loading capacity above the previous stage. For example, ONAN/ONAF/ONAF would be considered the most used liquid immersed power transformer design used in substation applications throughout the US. ONAN/ONAF/ONAF indicates three stages of cooling ratings are available. The first, as we learned above ONAN, being a natural convection of oil through external cooling, such as radiators. The second stage of cooling is the addition of a bank of cooling fans ONAF and the third being the addition of one more back of cooling fans. Each stage effectively has a rating at which the transformer is capable of being loaded to per the design requirements.

The cooling types previously listed are certainly not all inclusive, there are many other classifications, but this would be primarily what we see used most often today in the US market.

Liquid immersed power transformer cooling systems are essential for ensuring the reliable and efficient operation of these critical components in electrical grids. By effectively managing heat generation and dissipation, these systems play a vital role in preventing equipment failures, minimizing downtime, and maintaining power quality.

Cooling Control

Traditionally we have measured transformer temperatures via mechanical gauges for values such as Liquid and Winding Hot-Spot Temperature then utilized these temperatures to appropriately regulate the cooling systems such as fans or pumps. Many advances have been made over the years to greatly improve the mechanisms in which we use today to make the decision of when to operate each stage of cooling.

Transformer cooling control systems, sometimes called ETMs, are designed to maintain optimal operating temperatures by precisely regulating the cooling mechanisms. Strategically placed sensors monitor temperatures and other transformer parameters allowing the control system to determine the appropriate cooling response. For example, if the winding hot spot temperature rises above a predetermined threshold, the system might call for a bank of fans or initiate oil circulation. Conversely, if the temperature drops below the desired range, cooling mechanisms may be reduced to conserve energy. This dynamic control ensures that the transformer operates efficiently and safely, preventing overheating and extending its lifespan.

Conclusion

Liquid immersed power transformer cooling systems are essential for ensuring the reliable and efficient operation of these critical components in electrical grids. By effectively managing heat generation and dissipation, these systems play a vital role in preventing equipment failures, minimizing downtime, and maintaining power quality. The selection of an appropriate cooling system depends on factors such as transformer size, loading conditions, and environmental considerations.

Recent innovations in cooling control systems have significantly improved the precision and efficiency of transformer temperature management. Advanced sensors, data analytics, and automation technologies enable more accurate monitoring and control of cooling mechanisms, leading to optimized performance and energy savings. These advancements are crucial for ensuring the long-term reliability and sustainability of power grids.

Trent Williams is an Applications Engineer at Advanced Power Technologies with 10 years of experience in power transformer monitoring, product application and development. He obtained his BSEE from Wright State University. He is a member of IEEE PES, IEEE Transformer Committee, and technical paper author.

This article was originally published in the December 2024 issue of the Insulation Systems magazine.

View Magazine