In this issue we have the continuation of Red Talks, a series of interviews with subject matter experts. We have asked the leader of Red Talks, Lee Murray, to continue to provide his Red Talks with SME’s central to issue within the power system. The idea of Red Talks came from discussions with leaders in so many disciplines within industry, blossoming this year with the official launch of Red Talks and we are proud to present them as a Byline. But what is Reliability by Design?

Reliability Engineering in Asset Design: Ensuring Long-Term Performance in Power Systems

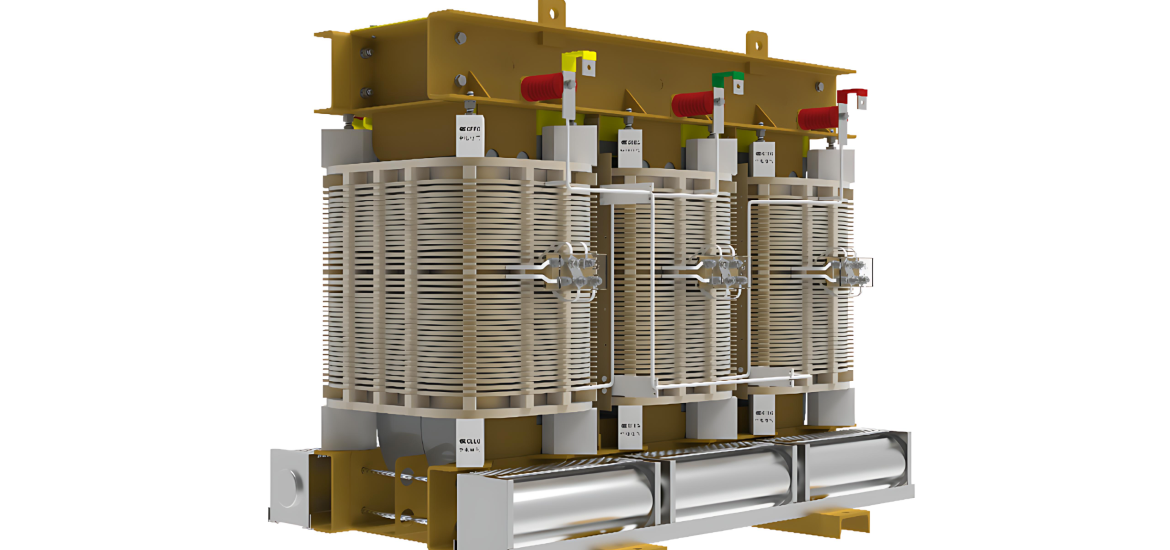

Let’s first look at the design and operation of critical infrastructure, particularly within the power sector. Reliability is not just a desirable feature-it is a necessity. Reliability engineering plays a foundational role in ensuring that assets such as power transformers, substations, and entire power systems operate effectively over long periods under a wide range of conditions. With so many extreme conditions affecting the energy grid, there is a need not only for the science of reliability, but the art of reliability. Given the centrality of electrical power to every facet of modern society, ensuring that these systems are robust, predictable, maintainable and resilient is both a technical and economic imperative.

With so many extreme conditions affecting the energy grid, there is a need not only for the science of reliability, but the art of reliability.

What is Reliability Engineering?

Let’s begin at the beginning. What exactly is the discipline of Reliability Engineering? It is a discipline focused on ensuring that systems and components perform their required functions under stated conditions, which might change well after you have set things up for a set of circumstances that no longer exist, and for a specified period of time. In the case of transformers that period was thought to be 20 years. With transformers in the grid at 40+ years old, now what? Did we over-engineer? Will that continue so that the transformer designed today will meet the same fate as the over-designed one made in 1976?

In the context of power systems, this means designing assets that can withstand environmental stresses, electrical surges, mechanical fatigue, and human error-without unplanned downtime or performance degradation. But will they last 40 years? Or should we begin to plan for the next generation asset aging more after 20 years and not expect them to last much longer? If I owned a transformer manufacturing plant, I would want to know, because the capacity that meets the needs of industry today might not be able to meet the needs in the future. Or vice versa, if I overbuild my capacity and must downsize to meet a smaller market, which happened in the late ‘70s and ‘80s, what impact will that have on the viability of my company.

Long-Term Reliability: A Design Priority

Long-term reliability is especially crucial for high-value, long-lifecycle assets such as power transformers. A single failure can result in extended outages, costly repairs, and significant economic losses. Therefore, reliability must be embedded at every phase of an asset’s lifecycle-from conceptual design and material selection to manufacturing, operation, and maintenance planning. Since most major assets are purchased to meet specific expectations, reliability becomes a function of anticipating those specifications.

A key strategy in reliability engineering is the application of Failure Modes and Effects Analysis (FMEA) and Root Cause Analysis (RCA) to identify vulnerabilities early in the design process. These methodologies allow engineers to anticipate where and how an asset might fail and implement design features that either eliminate these failure points or reduce their impact.

Materials and Environmental Considerations

Material science plays a critical role in long-term reliability. We know that the insulation materials used in transformers degrade over time due to thermal and electrical stress. Selecting materials with proven long-term performance characteristics—and designing the system to minimize stress on those materials—can extend asset life significantly. Additionally, corrosion resistance, mechanical robustness, and thermal stability must all be considered, especially for outdoor components exposed to harsh climates.

Environmental considerations also guide design decisions. Power systems must remain reliable in the face of environmental variability, including temperature extremes, humidity, seismic activity, and lightning strikes. Reliability engineering involves designing for these scenarios using standards such as IEEE, IEC, and ANSI guidelines to ensure consistency and robustness. But will the environmental factors we will see in 2 decades be the same as what we are seeing today?

Predictive Maintenance

Predictive maintenance is a relatively modern evolution of reliability thinking. By using sensors and digital monitoring systems, operators can track asset performance in real time and predict when maintenance is needed before a failure occurs. This approach minimizes downtime, reduces the risk of catastrophic failures, and ensures the asset remains within its design performance envelope throughout its lifecycle

Reliability engineering is not a one-time activity; it is an ongoing commitment embedded in the DNA of asset design, particularly in power systems where continuity of service is critical.

The Future of Reliability Engineering

As the power grid evolves to incorporate renewable energy, distributed generation, and smart grid technologies, the demands on reliability engineering are growing more complex. The integration of intermittent power sources and sophisticated control systems introduces new failure modes that must be accounted for in design and analysis.

What do we see in the future for Reliability Engineering by Design? We will increasingly leverage data analytics, machine learning, and in some cases digital twins to simulate and predict asset behavior under a wide range of scenarios. These technologies will enable more accurate lifecycle planning and condition-based maintenance strategies

Reliability engineering is not a one-time activity; it is an ongoing commitment embedded in the DNA of asset design, particularly in power systems where continuity of service is critical. Through thoughtful design, rigorous analysis, and proactive maintenance strategies, engineers can ensure that assets like power transformers remain reliable, safe, and efficient for decades—supporting the backbone of modern society.

This article was originally published in the June 2025 issue of the Innovations in Design, Manufacturing & Supply Chain magazine.

View Magazine