At the start of this month, I had a chance to sit down with a good friend and advisor, Chris Gerber during CWIEME Berlin. While discussing the state of the transformers market and supply constraints, the topic of transformers services came up. Chris has a long track record of asset management and transformer replacement in utilities as well as leading the service business unit of transformer OEMs.

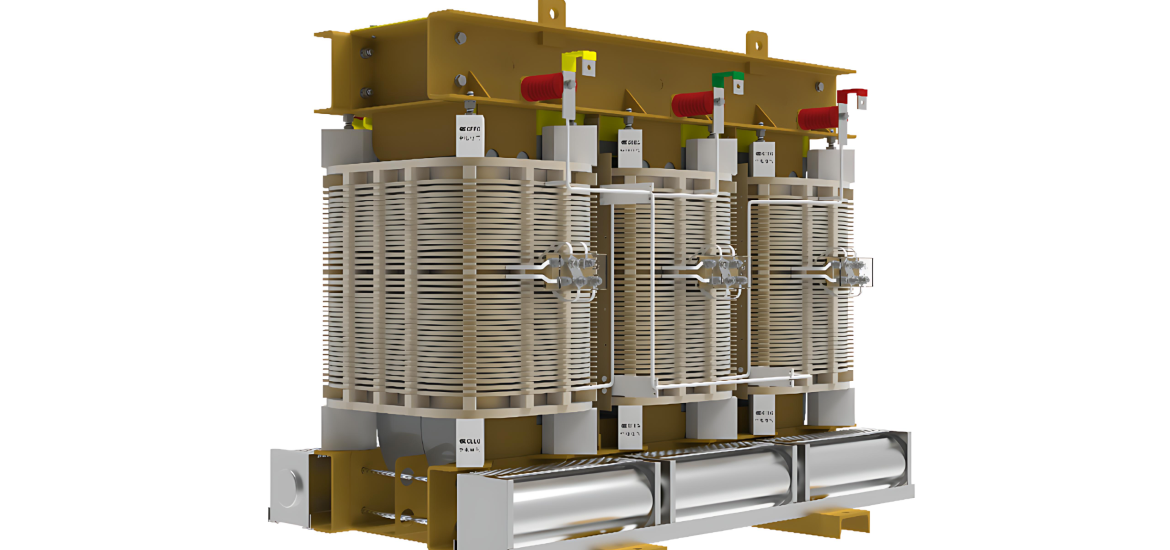

The concept of transformer lifecycle extension through refurbishment is not a new one. With the electrification and rapid integration of renewable energy, the need to upgrade the power grid, and the power transformers within, is accelerating at scale. However, in some regions, the transformer supply is not able to catch up with the increased demand at this pace, resulting in lead times for new transformers being significantly higher. Utilities are therefore looking to extend the service life of their existing transformers, bringing transformers service business into sharp focus as a means to alleviate the long lead times for new transformers.

This article is a summary of our discussion on the basics of a transformer service business, and the critical elements needed to drive a high-margin and high-growth transformer service organization.

New vs. Renewed: Choosing the Best Path for Transformer Assets

For end-users, utilities and industry, the answer is relatively straightforward: if there is sufficient funding and no significant time constraints, opting for a new transformer is typically the preferred route, especially when long-term reliability and performance are priorities. However, in today’s market, where lead times are extended and transformer prices have risen sharply, refurbishment has become an increasingly viable and attractive alternative for many utilities seeking to extend the life of their assets without the costs and delays associated with full replacement.

A refurbished transformer is often preferred by utilities when two conditions are met:

- The total refurbishment cost, including some margins, falls on average between 60% and 75% of the price of a new transformer

- The lead times are significantly lower than getting a new transformer.

In such cases, provided the transformer ratings are to remain the same, the transformers are typically assessed, windings are rewound, cores normally stay the same, oils are replaced, as well as other auxiliary components are changed, typically taking between 6-12 months depending on the size of the transformer. The option to change the transformer ratings, through reverse engineering of the original design, is also possible. Such service can be carried out by the Original Equipment Manufacturer (OEM) brand supplying the unit, or by a brand agnostic third party transformer service provider, as discussed ahead.

Key Elements of a Transformer Service Organizations

Typically, there are two types of transformer service providers:

- OEM service organizations that offer reconditioning and servicing the transformers they produce, linked to the specific factories the units are produced in.

- Independent companies that specialize in transformer maintenance, repair, and life-extension services, typically started by people with roots in the OEMs.

While major OEMs have an advantage in this business, as often the utilities approach the original OEM for repairs and refurbishments, and for transformer components, standalone service businesses can also carve out a share through a competitive edge strategy, business plan and execution. Regardless of the fact as to whether a services organization is directly linked to a specific OEM or an independent services provider working on all makes of transformers, the following key elements are required to ensure competitive success:

Engineering-driven technical team: A transformer manufacturing OEM often relies on a team of experienced engineers working behind the computers with complex designs, utilizing advanced tools and data to diagnose and resolve complex transformer issues. On the contrary, service organizations rely on skilled technicians who understand the product, its operations, and behavior under various circumstances and environmental conditions. They excel at the following without needing elaborate transformer designs:

- Dismantling the transformer

- Diagnosing and identifying necessary repairs

- Implementing Innovative, practical solutions

- All while executing work in a cost-effective and time-conscious way.

Efficient tools and equipment: One of the most critical aspects of a transformer service organization is whether the work is performed on-site or off-site. This decision carries significant operational implications, particularly because transformer service often involves handling the oil. To make it work, the service team must be equipped with essential infrastructure, including:

- Oil pump and vacuum unit

- Dedicated storage space for reused oil

- Oil filtration or regeneration plant

- Capability to obtain and analyze oil samples

- Winding machines and capacity

- Sufficiently large cranes for lifting and untanking

- High voltage test equipment to replicate the original factory acceptance test (FAT)

Additionally, having the correct set of hand tools for performing precise repairs is equally essential to ensure quality and safety during the process.

What makes a service organization successful?

What separates a profitable transformer service provider from the rest goes far beyond technical capabilities. Typically, service businesses can offer relatively decent gross margins between 30-60% with an EBITDA between 10-15% if running properly. To achieve these and make a service business high performing, a company must master three core business elements:

Technical Operations: A service organization must ace in its technical operations, supported by a competent, service-oriented, solution-driven technical team. Ideally, the team members should be the ones with experience in transformer manufacturing, end assembly, experience in building and disassembling transformers, and having a drive to solve complex technical challenges instead of a mundane job. A technical team that is proactively prepared, having no issues in “picking up the phone and responding to emergencies in the middle of the night”, is critical for this business’ success.

Operational Management: The second element which is crucial for success is having an operational management that understands the scope of the project and its requirements. Especially in the case of refurbishment projects, where well-defined milestones are crucial for tracking progress and ensuring timely delivery, having strong project management skills to manage these projects for the cost, quality and timeline are essential. And lastly, strong communication skills for coordination with the customer throughout the process are key to building trust and maintaining long-term engagement.

- Marketing and Sales: Lastly, having great marketing in place, to establish the credibility and visibility of a service organization, highlighting the company’s capabilities, track record and credentials of the team is necessary. Difference in this case, from typical transformer OEMs is that, while the transformer OEMs are marketing to promote the brand and the product, the marketing in a service organization needs to focus on the organization, the technical team within the company and their experience and capabilities.

How does the future look like?

With increased lead times and skyrocketing transformer prices, the opportunity to grow the transformer service business is substantial, especially for refurbishing the large power transformer units. To capitalize on this momentum, it is essential to truly understand the customer base. If established relationships already exist, the focus needs to be on exploring their evolving needs in greater depth and tailoring the approach accordingly.

Lastly, the service businesses must think beyond repair, maintenance, and spare parts. A consciously formulated strategy around transformer refurbishment, including a technical team able to deliver complex refurbishment works, a project management team able to ensure timely delivery and a sales and marketing team that understands the intricacies of transformer refurbishment and confidently communicates its value, can really position a transformers service business for sustained growth in the current rapidly evolving market landscape.

Hassan Zaheer

Managing Partner & Chief Operating Officer

Hassan is the Managing Partner & COO at PTR Inc. based in Abu Dhabi, UAE. With more than a decade of experience in the energy transition space, Hassan advises various Fortune-500 and blue-chip clients in the electrical infrastructure sector to sustainably grow their businesses, both through custom consulting work, marketing support services and tailored research reports by PTR, helping their executive management and boards make data driven strategic decisions. Hassan is also a Member of the Advisory Board for CWIEME Berlin and MENA EV Show, part of the Executive Editorial Board of APC Media and an advisor to the educational non-profit Better Humans Academy.

Hassan has a tech background with a Masters in Power Engineering from the Technical University of Munich (TUM) and a BS in Electrical Engineering from the Lahore University of Management Sciences (LUMS). Additionally, he is also an Alumni of the Center for Digital Technology & Management (CDTM).

Chris Gerber

Managing Partner & Genesiss Consulting

Chris Gerber is a former Transformer OEM CEO with noticeable experience in the transformer industry having worked for some of the most significant independent transformer companies in Europe. He has worked for and with some of the most noticeable transformer utilities in Africa, the Middle East, and Europe. He currently consults, specializing in strategy, business development, mergers and acquisitions, and IP transfers.

His experience in Mergers & Acquisitions in the transformer industry and his recent research on M&A ensures unique insights into this specialized field. He is the Managing Partner and founder of GENESISS as well as GENCON Consulting and a member of the Virtual Advisory Board. Chris advises PTR Inc. Yash HighVoltage, CWIEME Berlin, and STS Capital, and is also a member of CIGRE

This article was originally published in the June 2025 issue of the Innovations in Design, Manufacturing & Supply Chain magazine.

View Magazine