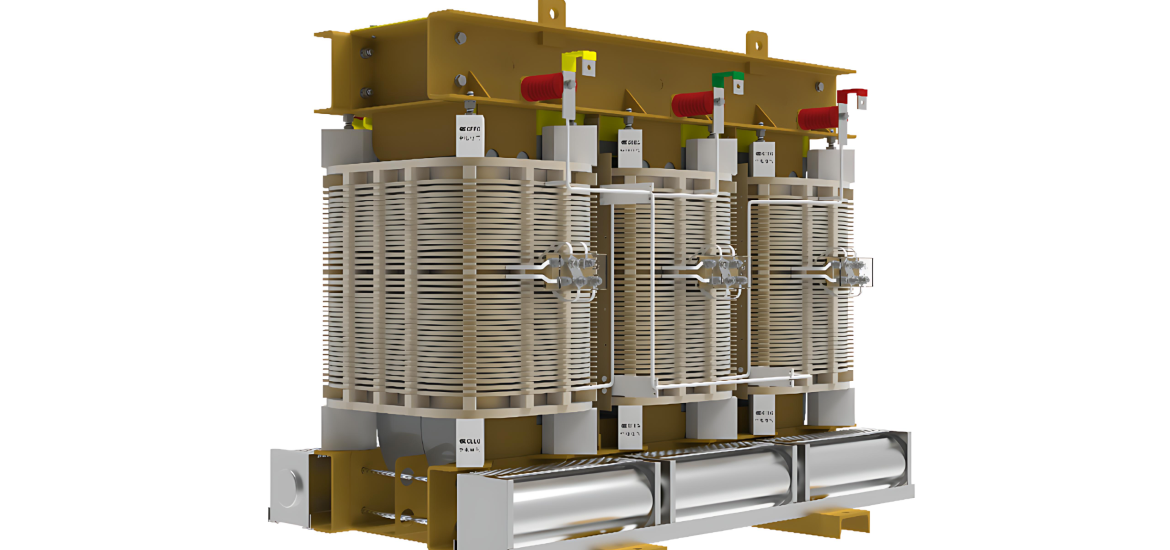

When a transformer leaves the factory, its efficiency is recorded. But once it’s installed in the field? That number often goes unverified. For most distribution and renewable energy sites, transformer losses are typically assumed, rather than measured.

That’s a risk. Utilities need to reduce carbon emissions, extend asset life, and justify investment decisions using complex data, not assumptions. Without verified performance in the field, asset managers are left to make critical calls without the full picture.

The TAU3 changes that. It’s a portable test set that can accurately measure total transformer losses — both load and no-load — on-site. And because it’s integrated into the same device field teams already use for turns ratio and winding resistance tests, it fits naturally into existing workflows.

Why On-Site Efficiency Testing Matters

Transformer losses are one of the biggest contributors to inefficiency across the grid. Even small improvements, when scaled across thousands of units, can deliver major savings. But the reality is, most utilities don’t test transformer efficiency after installation. It’s simply not been practical — until now.

Factory tests are useful at the point of manufacture, but they don’t account for transport damage, installation conditions, or early signs of deterioration. In a world where every kilowatt matters, relying solely on factory data isn’t enough.

What We Mean by Efficiency

In this context, efficiency refers to how effectively a transformer converts input power into output power. Losses come in two main forms:

- No-load losses: caused by energizing the core, present even without load.

- Load losses: caused by current flow through windings and connections.

Lower losses mean better performance and lower running costs. For asset managers, understanding this data is critical — not just for technical evaluations, but for budgeting, planning, and environmental reporting.

The Practical Barrier — And Why It’s Been a Blind Spot

Traditionally, measuring these losses required large, factory-based equipment and highly controlled environments. That’s why field-based efficiency testing has lagged behind — the tools simply weren’t there.

Instead, utilities have relied on nameplate data, assumptions, or periodic lab tests to estimate performance. That leaves a huge gap in understanding how transformers actually behave in real-world conditions — particularly in remote or renewable applications where access is limited.

Enter the TAU3: Built for the Field

The TAU3 from Megger is currently the only portable device that allows field teams to measure total transformer losses accurately. It’s designed for use in the environments where most transformers operate — substations, renewables, and distribution networks.

It measures current and voltage inputs to calculate total losses. While it’s not a full power analyser, it gives operators the key figures they need — quickly, safely, and without needing to reconfigure their test routine.

Critically, the TAU3 performs these measurements at the same time as standard tests like turns ratio and winding resistance. That means no extra setup, no additional hardware, and no new process to learn.

Use Cases That Add Real Value

Adding efficiency testing to field routines opens up several valuable use cases:

- Verifying supplier claims: Efficiency can be checked upon delivery, before the transformer goes into service.

- Supporting condition assessments: Efficiency data complements other diagnostics to give a more complete picture of asset health.

- Planning replacements: When budgets are tight, knowing which units are underperforming helps prioritise investment.

- Carbon reporting: As more utilities adopt ESG targets, verified loss data becomes a powerful tool for meeting regulatory requirements.

This is especially critical for distribution networks, where tens of thousands of transformers are deployed. These units represent a significant proportion of system losses and are often the least monitored.

Making Field Efficiency Testing Standard Practice

Field-capable efficiency testing shouldn’t be a specialist task. It should be part of the standard testing workflow — easy to perform, easy to repeat, and easy to trust.

The TAU3 makes this possible. It integrates into existing routines, fits into the technician’s toolkit, and delivers data that directly supports strategic asset decisions, without adding new complexity or equipment.

It’s not a new device to learn. It’s added value from the multifunction test set you’re already using.

Utilities are under growing pressure to do more with fewer resources. In that environment, being able to measure actual transformer performance — not just estimate it — is a critical advantage.

Efficiency is no longer something you need to guess. With the right tools, you can measure it, manage it, and improve it.

Megger Group Limited

T +44(0)1304 502100. (Switchboard)

This article was originally published in the June 2025 issue of the Innovations in Design, Manufacturing & Supply Chain magazine.

View Magazine