COMEM Group provides world-class consulting services, product solutions, and after-sales support during the entire transformer lifecycle for transformer manufacturers, service organizations and end-users. Our manufacturing units are in Italy, China, Germany, and Brazil. We manufacture a wide range of components and bushings for power and distribution transformers. We provide also fiber optic systems for precise and reliable temperature measurement. Our products are designed to be compatible with many technical standards, and different transformer brands and are interchangeable with equivalent models of third-party manufacturers. Local support is guaranteed worldwide through an extensive network of agents and distributors called Authorized Partners. We can also support our customers with an on-site transformer service from general maintenance and testing to digitalization of your transformer.

Our offering at a glance

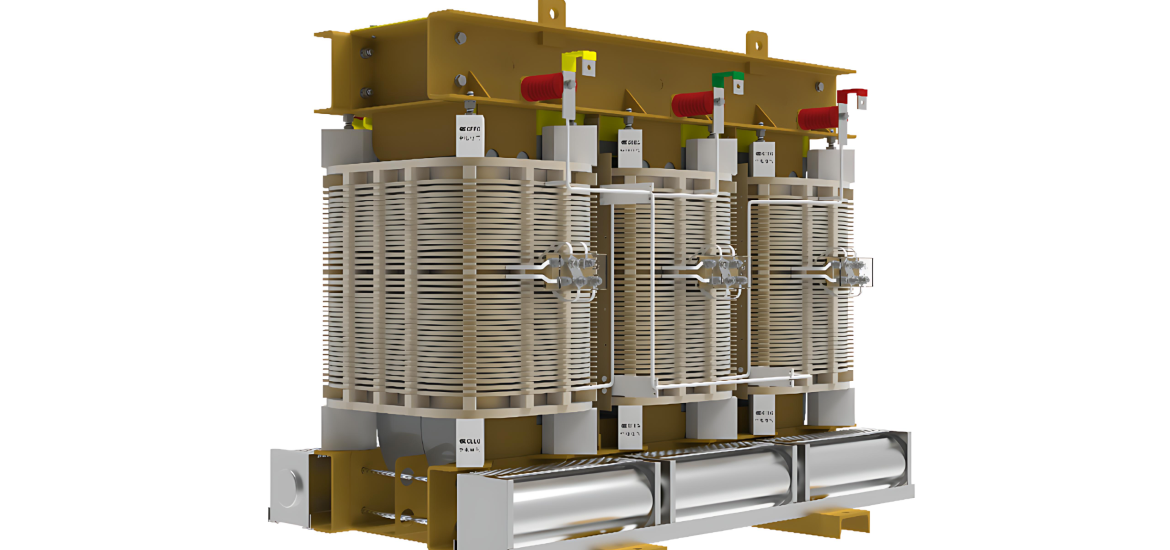

Bushings cater to a wide variety of requirements based on transformer design, current capacity, and rated voltage. The range includes:

Porcelain oil bushings for low-voltage and medium-voltage applications

• Nominal voltage: 1 – 52 kV

• Rated current: 250 – 8000 A

• Compatible with EN and DIN standards

Epoxy resin bushings for low-voltage and medium-voltage applications

• Nominal voltage: 1 – 42 kV

• Rated current: 250 – 8000 A

• Compatible with IEC standard

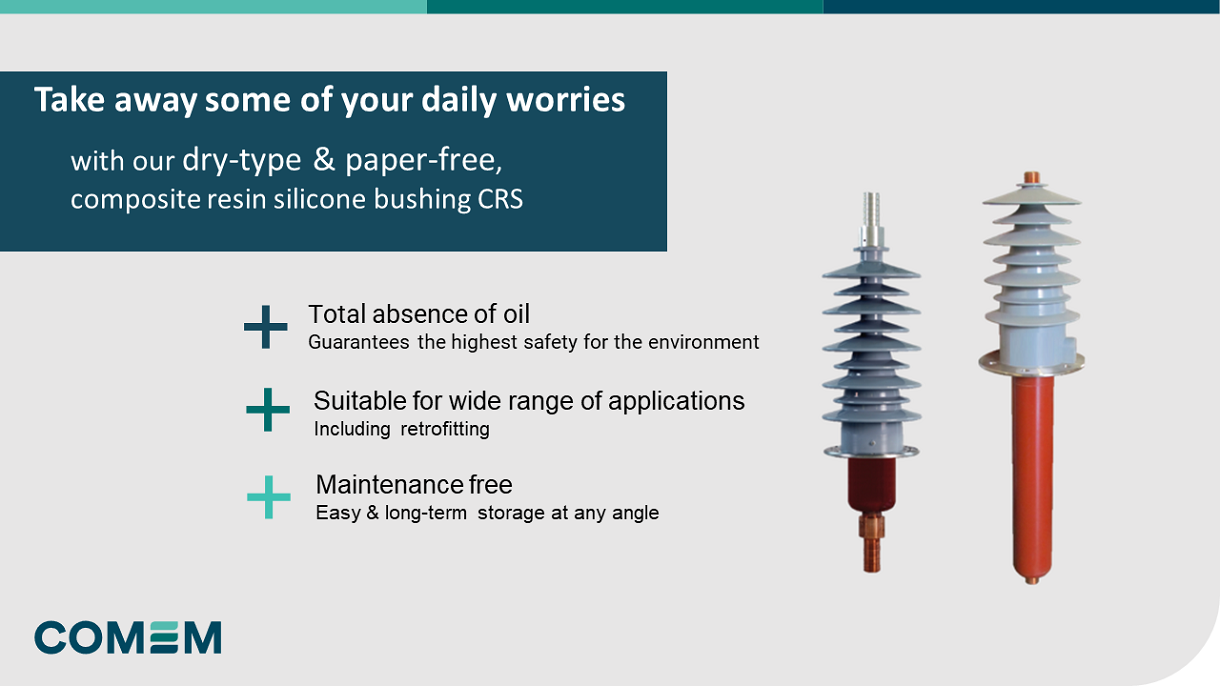

Resin silicon bushings

• IEC range: Um ≤ 72.5 kV, Ir ≤ 6300A

• IEEE range: Um ≤ 34.5 kV, Ir ≤ 3000A

• Qualified as per IEC60137 and IEEE C57.19.01- 2000

• Compatible with EN and DIN standards

Our offering at a glance

Essential for safe and efficient transformer operations, our conventional accessories are suitable for both new installations and retrofits. Options include:

• Dehydrating breathers

• Relays

• Liquid level indicators

• Pressure relief devices

• Temperature indicators

Digitalization and devices for smart transformer

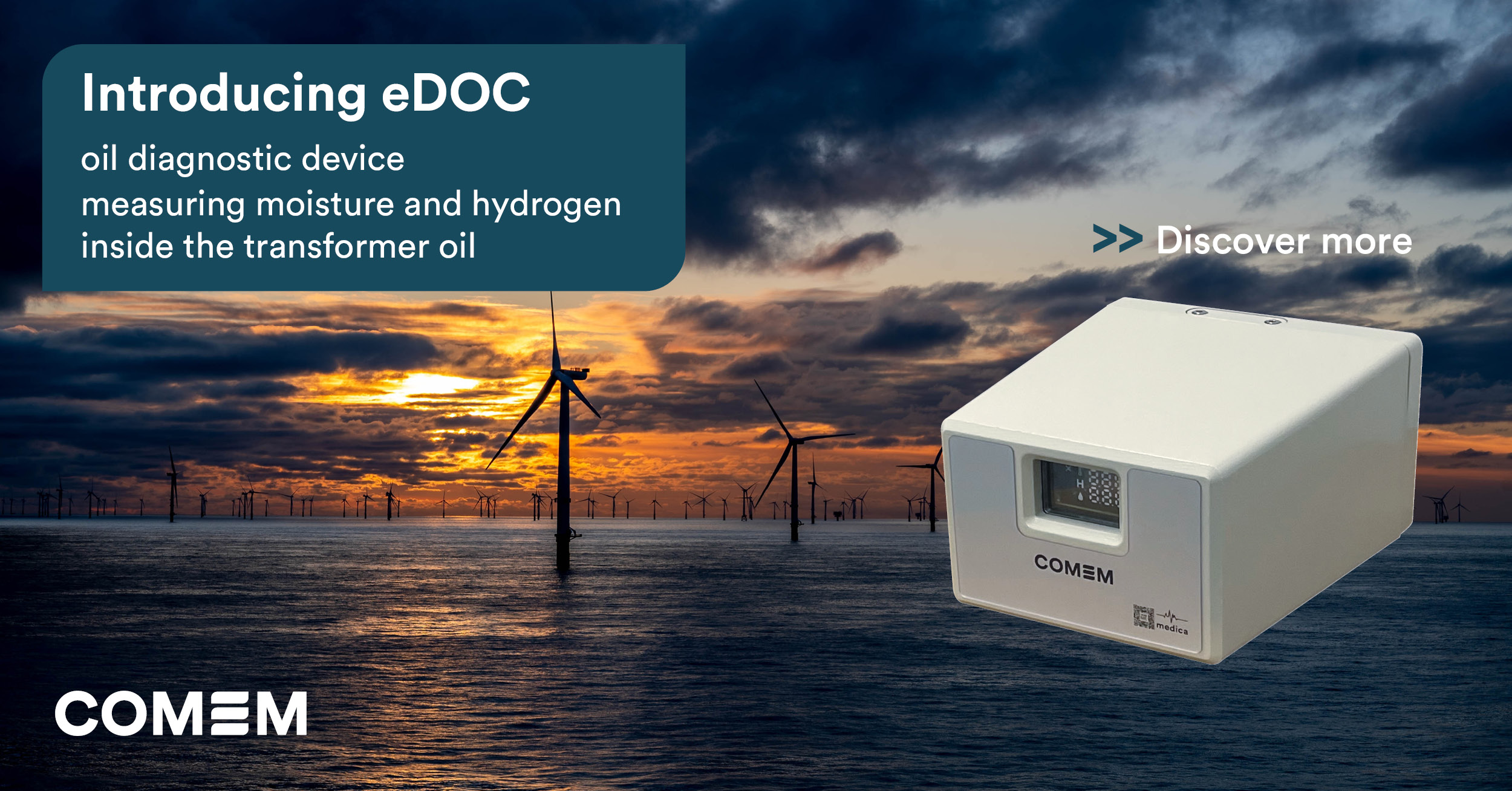

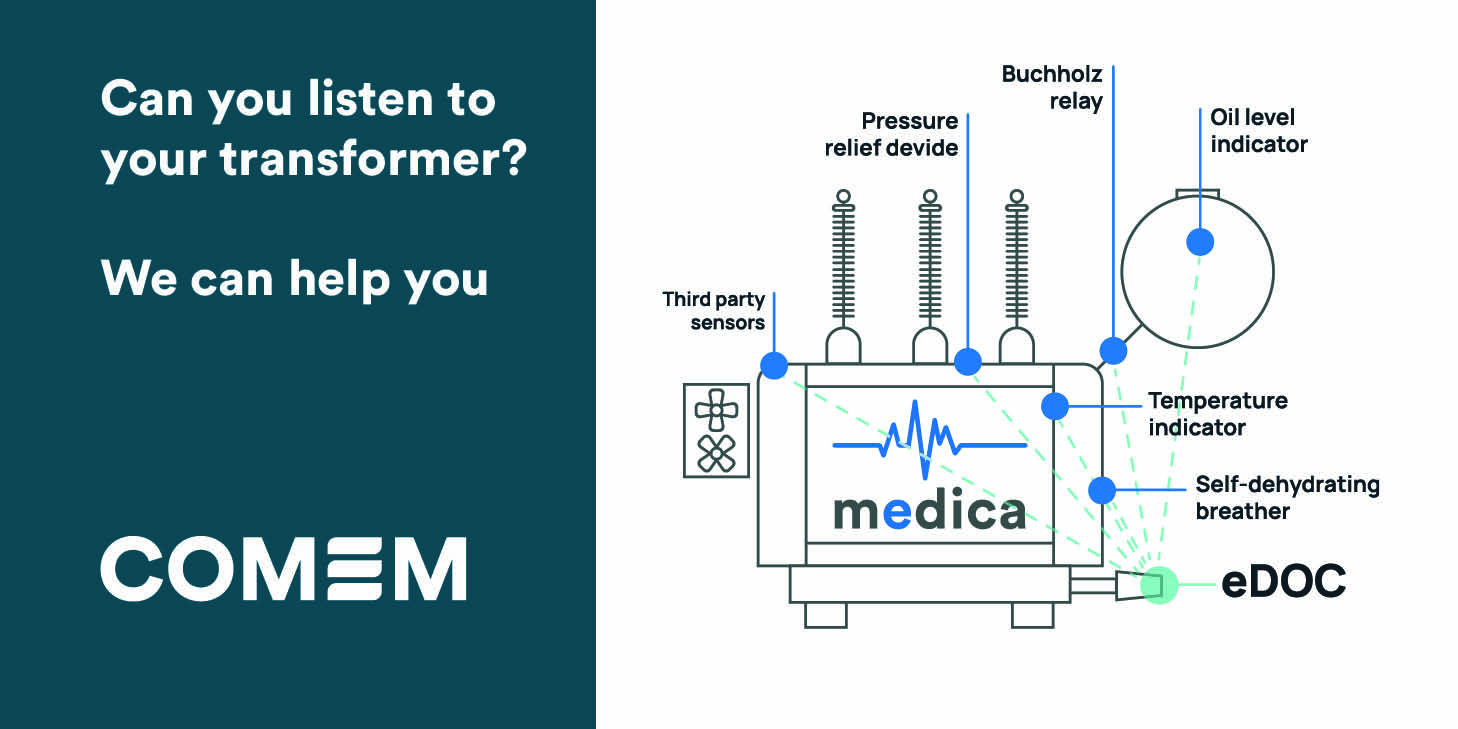

Transitioning from traditional grid systems to efficient smart grids is crucial. Our eDevices for smart transformers enable continuous monitoring and data gathering, allowing for remote or on-site data collection essential for predictive maintenance. Options include:

• Buchholz relays

• Data aggregators

• Liquid level indicators

• Oil diagnostic devices (DGA)

• Pressure relief devices

• Self-dehydrating breathers

• Temperature indicators

These devices can be installed on new transformers or retrofitted to existing

assets.

Fiber optic temperature measurement systems (FOTEMP)

Utilizing fiber optics for temperature monitoring allows continuous and accurate proactive measures to prevent supply compromise. The system consists of:

• Fiber optic devices

• Fiber optic sensors

• Fiber optic accessories

All our eDevices and Fiber optic systems can also be connected to third-party devices and are part of our modular monitoring ecosystem for transformer diagnostics MeDICA.

MeDICA, an open and agnostic Monitoring Ecosystem for transformer diagnostics, provides a complete solution that includes products and services that can enable a longer and more efficient transformer life cycle. By identifying and preventing premature transformer failures through monitoring, you can ensure business continuity and significantly reduce operational costs.

COMEM service offers a full range of on-site services from general maintenance and testing up to digitalization of the transformer. We can help you develop a sustainable and data-driven predictive maintenance strategy.

Contact us:

Follow us on:

Learn more on our website:

This article was originally published in the March 2025 issue of the Monitoring, Diagnostics, Maintenance & Reliability magazine.

View Magazine