Opportunity

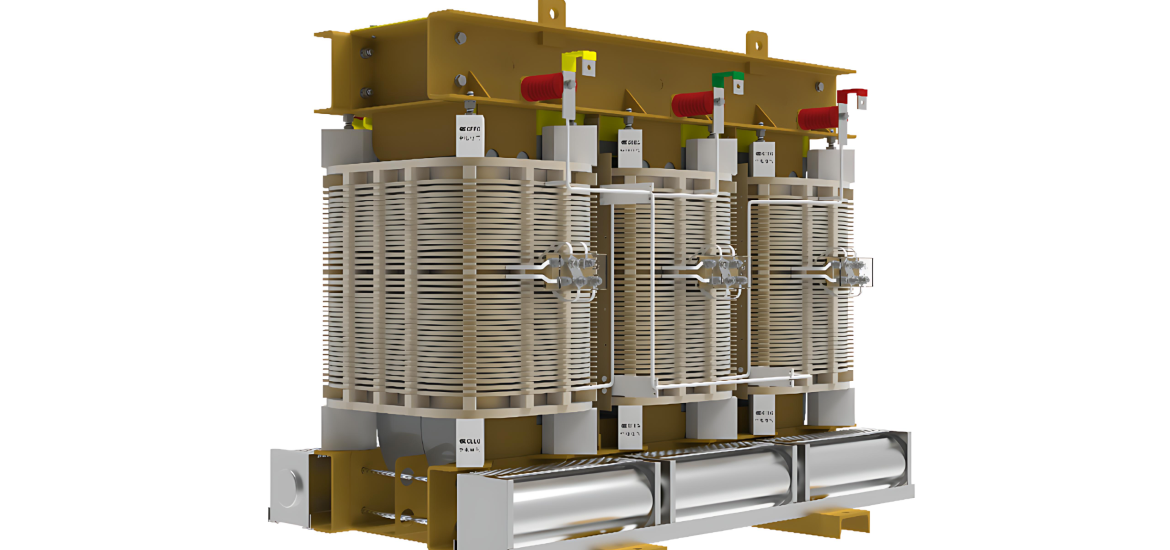

The people and companies that make up the transformer industry are a linchpin for world economic growth. Without transformers, there is no electricity. Transformers are the on- and off-ramps to electricity grids. The demand for electricity, not just for computer centers or transportation, but for the electrification of everything is increasing the demand for transformers.

Unfortunately, supply chain issues are causing long global transformer delivery times, limiting progress. Solving these issues is challenged by uncertainties in raw material availability, labor and automation costs, shipping costs, taxes, and tariffs.

The U.S. has an additional challenge. The life expectancy of a transformer is about thirty years and almost 75% of U.S. transformers are at least twenty-five years old. So, we are trying to grow when it is hard to stay where we are. Additionally, emerging technology is changing the load profiles served by the grid. For example, traditionally, transformers were more lightly loaded overnight allowing for cooling. The cooler operation meant slower aging during these periods. But emerging applications, like data centers and nocturnal battery charging to enhance dispatchability of power in the grid, limit transformer life by curtailing nighttime cooling.

Promise of Engineered Materials

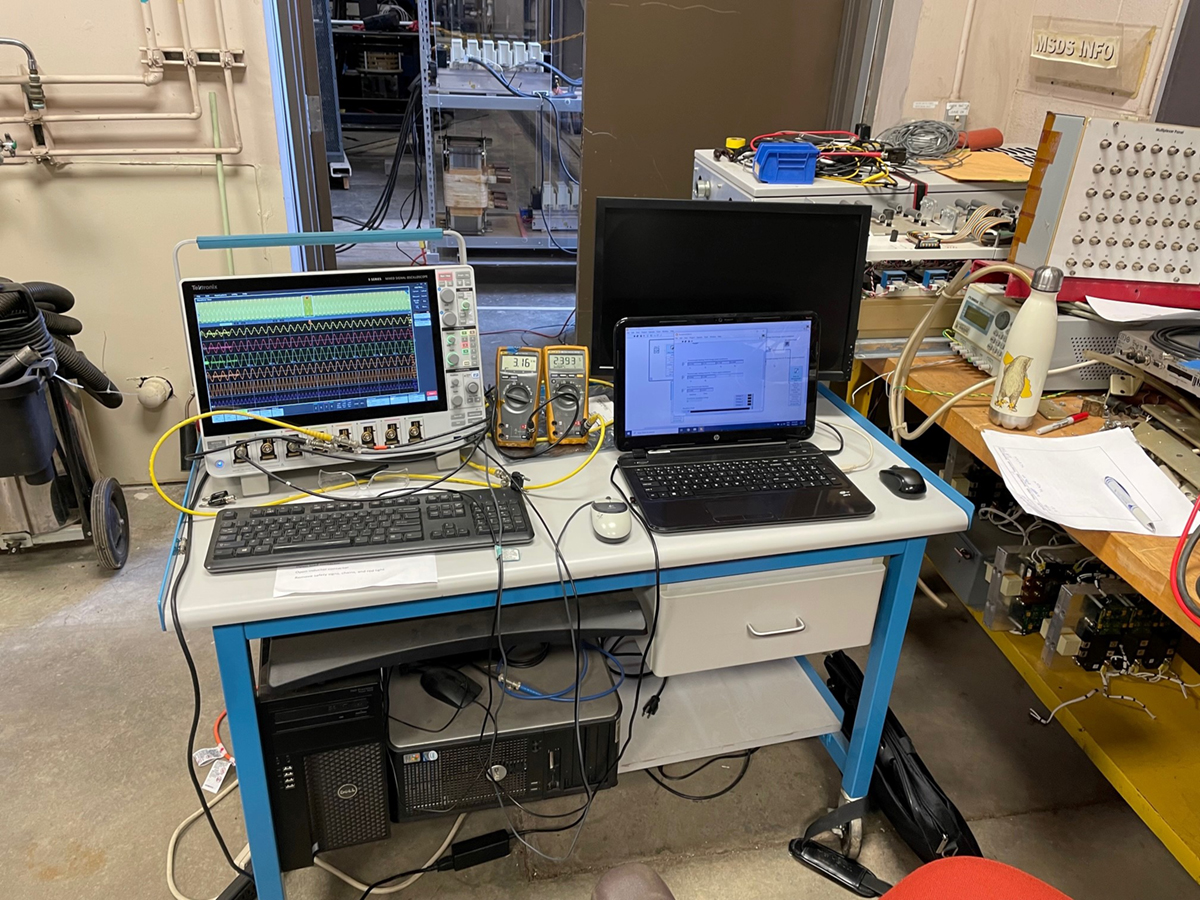

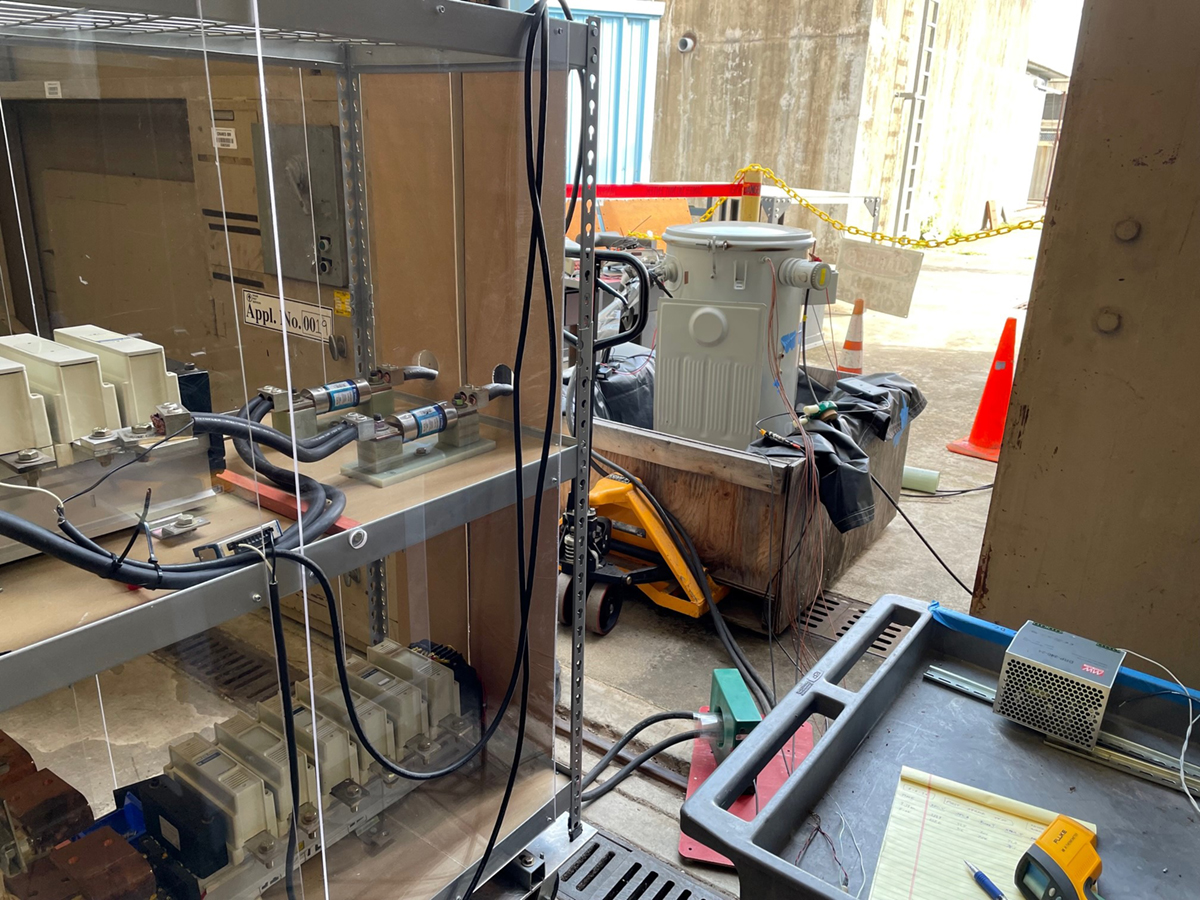

Research promises to nip potential problems due to emerging technologies in the bud by modifying conventional oil-paper insulation to increase transformer thermal life. The first research step determined, via modeling, opportunities for meaningful improvements. A thermal model was validated by measuring the temperature distribution in a transformer at operating voltage and current.

This model revealed that thermal life could be doubled by making a what appeared to be an achievable change in the thermal conductivity of the transformer’s oil-paper insulation. The remainder of the system could remain unchanged.

Specifically, increasing the thermal conductivity from the present value of 0.2 W/mK to 1 W/mK could double the thermal life. The life increase results from lower temperature under load. That resarch also showed that there were diminishing returns for further increases as other factors began to dominate. (Bilyaz, S., et al. “Modeling the impact of high thermal conductivity paper on the performance and life of power transformers.” Heliyon 10.6 (2024).

The Arrhenius equation has long reminded insulation designers, that small increases in temperature lead to significant aging in electrical insulation. The insight in the model was that a change in the thermal conductivity of a single insulating component in a complex transformer system led to cooler operation under all conditions. This leads to longer life. Funding by ARPA-E provided the research team with resources it needed to invent a paper that met the objective. A key to the advance was the addition of boron nitride (BN) patricles to the paper during manufacturing. This breakthrough paper was recently published, and the length of the author list reflects the multidisciplinary challenge. While the University of Texas at Austin has expertise in the electrical, mechanical, and thermal aspects, success requires more. It was necessary to team with experts on paper science and technology at the University of Maryland, Yale University, and the USDA Forest Products Laboratory.

The demand for electricity, not just for computer centers or transportation, but for the electrification of everything is increasing the demand for transformers.

In addition, the team included a retired faculty member from the Rensselaer Polytechnical Institute who pioneered the application of nanotechnology to electrical insulation.

The new insulation system builds on more than a century of commercial success using oil and paper in transformers. The significant improvements were replacing con ventional oil with a renewable and less flammable ester oil, an emerging industrial trend, and incorporating recent advances in microtechnology and nanotechnology.

Addressing the Challenges

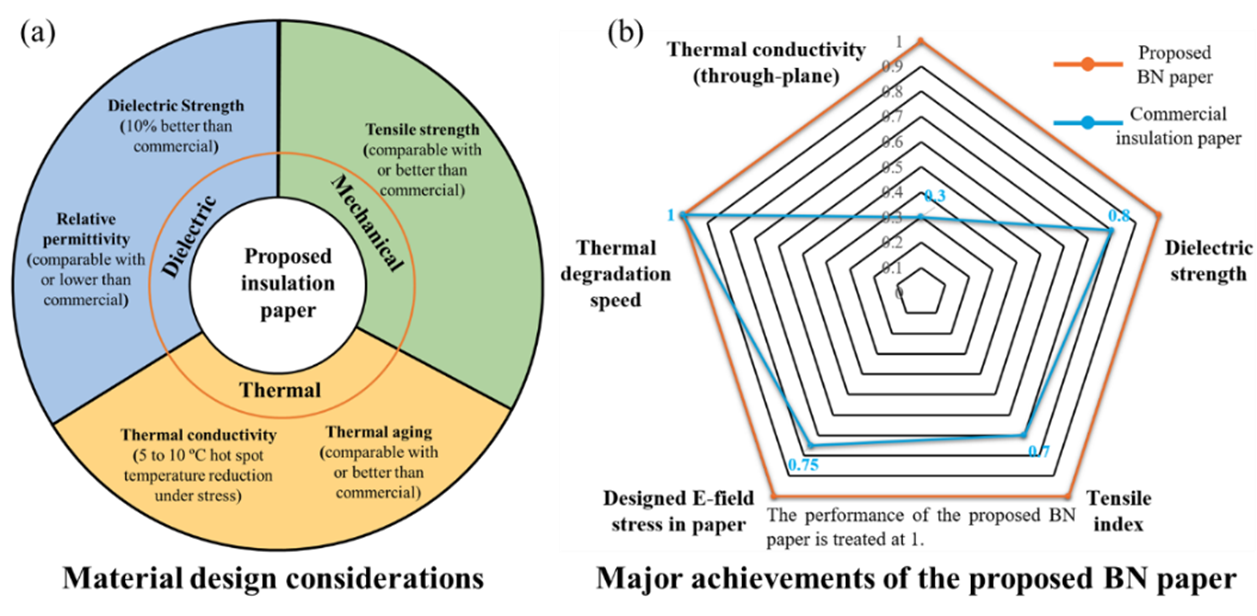

The thermal conductivity goal was met using 25 micrometer boron nitride particles. A design requirement, however, was to achieve thermal conductivity goals without sacrificing other important performance attributes.

The physics of electrical failure in this insulation system led to the boron nitride increasing the electrical breakdown voltage of this material over conventional oil paper systems. While this investigation found a combination of boron nitride particle size and density of particles in the oil-paper system that increased the electrical breakdown strength, additional research is needed to determine if better combinations are available.

Adding particles, however, reduced the tensile strength of the paper. The tensile strength is set by hydrogen bonding between cellulose f ibers. The particles reduced the number of bonding sites available, thus reducing the tensile strength. The solution was to add microfibrillated and nanofibrillated cellulose to increase hydrogen bonding. The additional hydrogen bonding enhanced the tensile strength by connecting the cellulose f ibers in the paper to one another.

The investigation found that adding boron nitride to achieve a density of 70 wt% of the kraft fibers increased the through-plane thermal conductivity from 0.1 W/m·K to 0.76 W/m·K with oil-impregnation.

But the addition of the particles reduces the tensile strength of the paper.

Further research showed that the addition of microfibrillated fibers to the kraft fibers permitted retention of 80% of the pre-particle tensile strength, partially compensating for the particle-induced reduction. Since this paper had high tensile strength, the reduction was judged to be acceptable as the resulting tensile strength still exceeded that of commercially available papers in use today. The boron nitride decreased the relative permittivity of the newly developed oil-paper insulation system. The decrease is helpful, as a greater share of electrical stress is supported by the novel paper that has adequate dielectric breakdown strength.

The significant improvements were replacing conventional oil with a renewable and less flammable ester oil, an emerging industrial trend, and incorporating recent advances in microtechnology and nanotechnology.

Overall, this implies that the present design of insulation paper fits the need of existing transformers. Thermal aging results indicated that neither the highly refined fibers nor the boron nitride significantly affected the thermal degradation rate of the paper.

The enhanced insulation paper yielded three times better through plane thermal conductivity, 23% higher dielectric strength and approximately 35% higher tensile strength than the commercial insulation paper with similar thermal degradation rates. This permits lower temperature transformer operation, while minimizing the need for transformer design changes.

The approximately 33% smaller relative permittivity than commercial paper provides additional potential benefit. It can further reduce the electric-field stress in the oil ducts of power transformers. This reduction is beneficial because oil ducts can support partial discharges, which shorten the transformer life.

The paper fabrication method is conventional and fits the current commercial paper production practice. It is commercially beneficial that any novel insulation paper leverages the existing papermaking infrastructure to minimize cost. While the processing costs should be comparable, the new paper adds material cost over conventional paper.

This figure summarizes the key parameters:

Future

There is evidence this is not just a one-off advance. The community may be witnessing the start of a new era of engineered electrical insulation. About the same time this paper on transformer insulation was published, a paper on alternator insulation was published by a group in India. They added boron nitride nanoparticles to the polymer used to insulate the stator and rotor in alternators. This too doubled insulation life.

While emerging material-enabled paths to power equipment with longer thermal life are being discovered, it is unlikely that these f irst approaches are the only or the optimal paths. The world benefits if this academic research, showing what is possible, triggers industrial development of what is practical and profitable.

As the underpinnings of the modern world become more electric, it is incumbent on the transformer community to find ways to enable the infrastructure needed for more abundant electricity, at a lower cost and with a smaller environmental footprint. Rapid adaptation of emerging beneficial technology is part of the solution.

Bob Hebner is an emeritus research profes sor at the Center for Electromechanics at the University of Texas at Austin. He is a life Fellow of the IEEE. His 200+ publications focus primarily on measurement technolo gy and materials characterization for grids and microgrids. A current research interest is in the development of commercially rel evant electrical insulating materials with high thermal conductivity. Nanotechnology may make it possible to achieve this long sought-after performance.

This article was originally published in the October 2025 issue of the Advanced Insulation Soulutions: Condition Monitoring for a Safer Grid magazine.

View Magazine